- Home/

- Category/

- Chrome-plated shaft, Shaft with base, Bearing/

- Rod end bearing

/ Coupling KR KRV

Coupling KR KRV

Buffalo eye bearing is a supporting accessory for gas cylinders, oil cylinders of all kinds. It is a type of bearing with a shaft mounted or mounted on the chassis, cylinders to ensure that the cylinder can perform a number of other tasks such as opening and closing the cellar lid, opening the car door, metal doors. type in the factory… in addition to the usual push and pull.

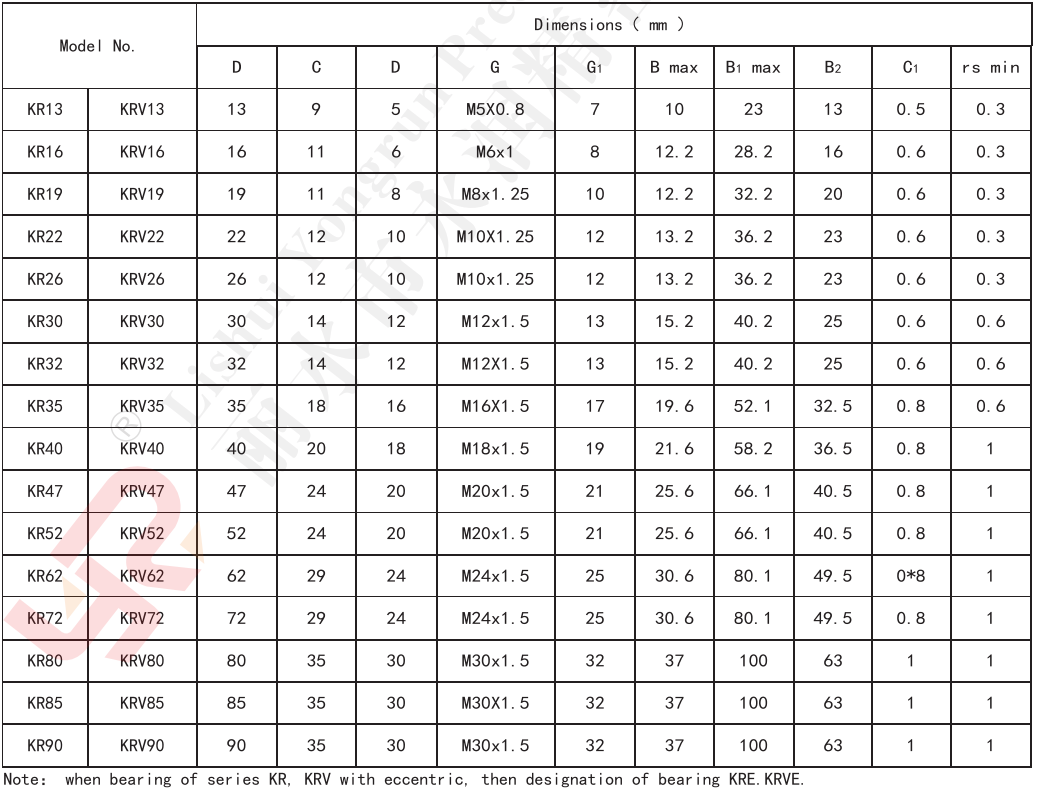

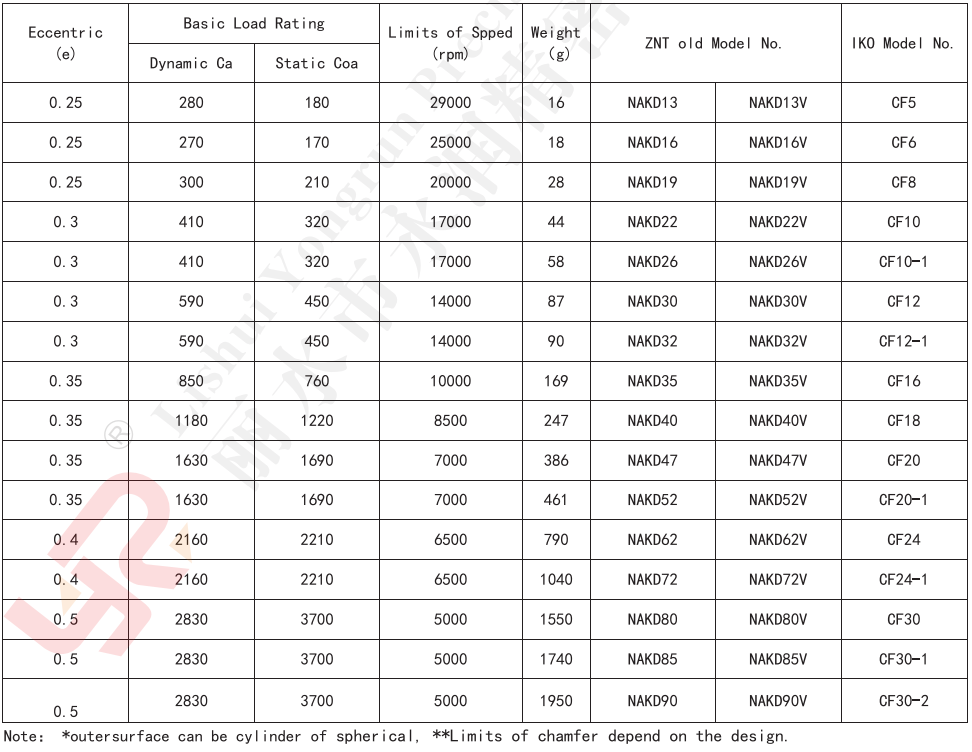

- KR13

- KR16

- KR19

- KR22

- KR26

- KR30

- KR32

- KR35

- KR40

- KR47

- KR52

- KR62

- KR72

- KR80

- KR85

- KR90

- KRV13

- KRV16

- KRV19

- KRV22

- KRV26

- KRV30

- KRV32

- KRV35

- KRV40

- KRV47

- KRV52

- KRV62

- KRV72

- KRV80

- KRV85

- KRV90

Description

Specification:

Feature:

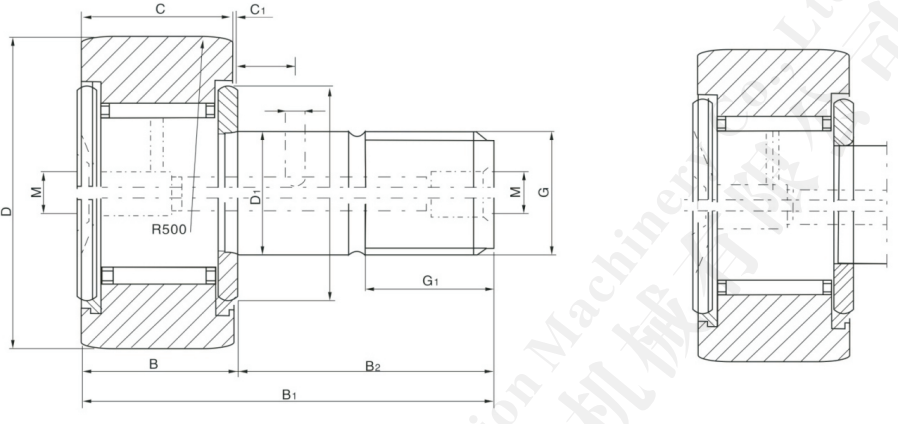

Its structure is divided into 2 basic parts: Bearing and body. The inner bearings are machined smooth, the outer ring is enclosed. The body will have threaded rings for tightening.

The advantages of buffalo eyeball joints are: Used for long-term systems. It is not necessary for the user to continuously clean and maintain it, whether in lubrication or non-lubricated working conditions. The outer layer is glossy, so it is dust-proof. Especially it is low friction operating.

Construction of buffalo eye bearings

A buffalo eye bearing will be divided into 2 parts that are head and body:

+ The head of the buffalo eye will have a structure consisting of a small inner circle located inside a corresponding outer circle. It is specialized for radial or axial loads.

+ The body will be extended with meticulously machined internal or external threads for installation on cylinder equipment. This body is also known as the threaded shaft.

All buffalo eye bearings are made from 100% metal. It can be stainless steel 304, copper, plated iron. These materials will help the device to be durable when working in environments with great force, pressure or corrosive and oxidizing media.

Application of buffalo eye ball joint

As we said above, there are many types of buffalo eye bearings that are divided into groups based on production characteristics, mounting type or type of operation. The variety of types will meet the needs of customers, especially when pneumatic and hydraulic applications are extensive in production and life.

Depending on the system as well as the parameters of the actuator cylinder, the buffalo eyes can be designed and machined accordingly.

The buffalo-eye couplings are small in size but have a large capacity, with a moderate deviation design will be used a lot in the aviation and space industries.

For large size buffalo eye bearings, special parameters will be suitable for jobs and systems with low vibration such as construction machinery, mining, machine assembly. machinery, mechanical engineering.

We can see buffalo eye bearings in the hydraulic systems of tractors, racing cars or boats with hydraulic steering, industrial machinery.