- Home/

- Category/

- Chrome-plated shaft, Shaft with base, Bearing/

- Rod end bearing

/ Coupling SA**T/K

Coupling SA**T/K

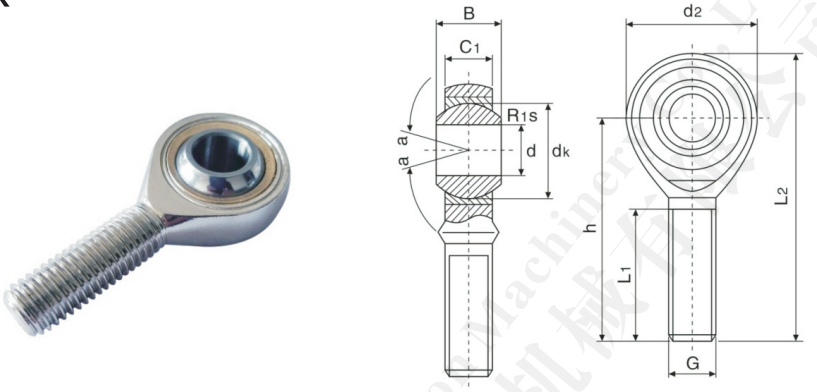

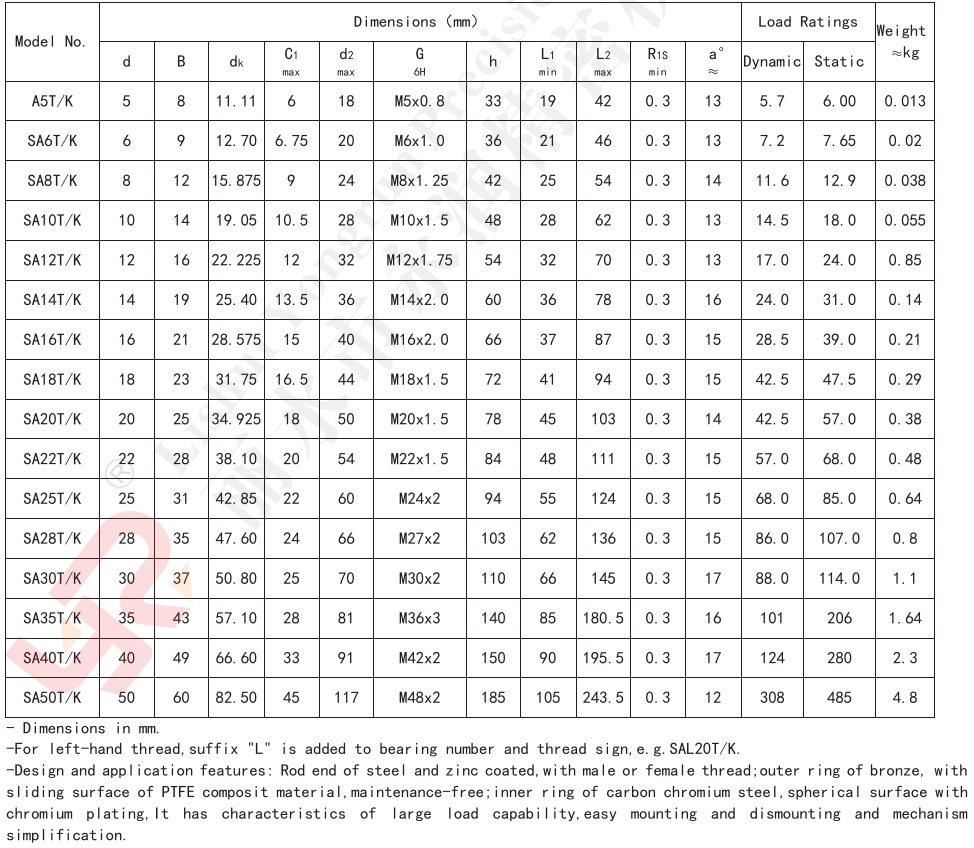

The SA Series Rod End Bearing (male thread) is a mechanical linkage component designed to transmit loads while allowing angular misalignment in pneumatic, hydraulic, and mechanical systems. It features a robust all-metal construction, a precision-polished inner ring, and a maintenance-free PTFE composite sliding surface, ensuring low friction, smooth operation, and long service life. With high load capacity, easy installation, and reliable performance, the SA series rod end bearing is ideal for industrial machinery, cylinders, linkage mechanisms, and motion control applications.

- SA5T/K

- SA6T/K

- SA8T/K

- SA10T/K

- SA12T/K

- SA14T/K

- SA14-1T/K

- SA16T/K

- SA18T/K

- SA20T/K

- SA22T/K

- SA25T/K

- SA28T/K

- SA30T/K

- SA35T/K

- SA40T/K

- SA50T/K

- SA5T/K SUS304

- SA6T/K SUS304

- SA8T/K SUS304

- SA10T/K SUS304

- SA12T/K SUS304

- SA14T/K SUS304

- SA14-1T/K SUS304

- SA16T/K SUS304

- SA18T/K SUS304

- SA20T/K SUS304

- SA22T/K SUS304

- SA25T/K SUS304

- SA28T/K SUS304

- SA30T/K SUS304

- SA35T/K SUS304

- SA40T/K SUS304

- SA50T/K SUS304

Description

Specification:

The Rod End Bearing, also known as a spherical plain bearing or “bi mắt trâu”, is a critical mechanical linkage component widely used in pneumatic, hydraulic, and mechanical transmission systems. Despite its compact size, it offers high load capacity, angular flexibility, and long-term durability, making it suitable for demanding industrial applications.

🔹 Structure of the Rod End Bearing

The rod end bearing consists of two main parts: the bearing head and the threaded body.

1. Bearing Head (Spherical Eye)

- Features a precision-polished inner spherical ring housed within a matching outer ring.

- Designed to withstand axial loads, radial loads, or combined loads.

- Allows a certain degree of angular misalignment, enabling smooth operation even under offset or misaligned conditions.

2. Body / Shank (Threaded Rod)

- The bearing head is integrated with an extended body featuring either male or female threads, depending on the model.

- Threads are precisely machined for direct installation on pneumatic cylinders, hydraulic cylinders, and mechanical linkages.

- This part is commonly referred to as the threaded shank, providing secure and adjustable mechanical connection.

🔹 Materials and Technical Characteristics

- Manufactured entirely from metal materials, such as SUS304 stainless steel, zinc-plated steel, or brass.

- The sliding surface is made of PTFE composite material, ensuring low friction, maintenance-free operation, and long service life.

- The outer surface is finely finished to resist dust adhesion, wear, oxidation, and corrosion.

- Suitable for harsh working environments involving high loads, pressure, vibration, or corrosive media.

🔹 Key Advantages

- Maintenance-free design, no frequent lubrication required.

- Low friction coefficient, ensuring smooth and stable movement.

- High load-bearing capacity and mechanical strength.

- Easy installation and disassembly.

- Reliable performance in both lubricated and non-lubricated systems.

🔹 Applications

Thanks to its wide range of sizes, thread types, and material options, rod end bearings are extensively used in:

- Industrial pneumatic and hydraulic systems

- Pneumatic and hydraulic cylinders

- Mechanical transmission and linkage mechanisms

- Industrial machinery and automation equipment

- Construction and mining machinery

- Aerospace and aviation industries, where compact components must handle high loads with angular movement

- Hydraulic steering systems for tractors, racing vehicles, ships, and marine equipment

- Heavy-duty industrial equipment with low vibration and high load requirements