- Home/

- Category/

- Airtac Pneumatic/

- Slide Table Cylinders Airtac

/ Airtac HLS / HLSL Slide Table Pneumatic Cylinder – Cross Roller Type, High Rigidity

Airtac HLS / HLSL Slide Table Pneumatic Cylinder – Cross Roller Type, High Rigidity

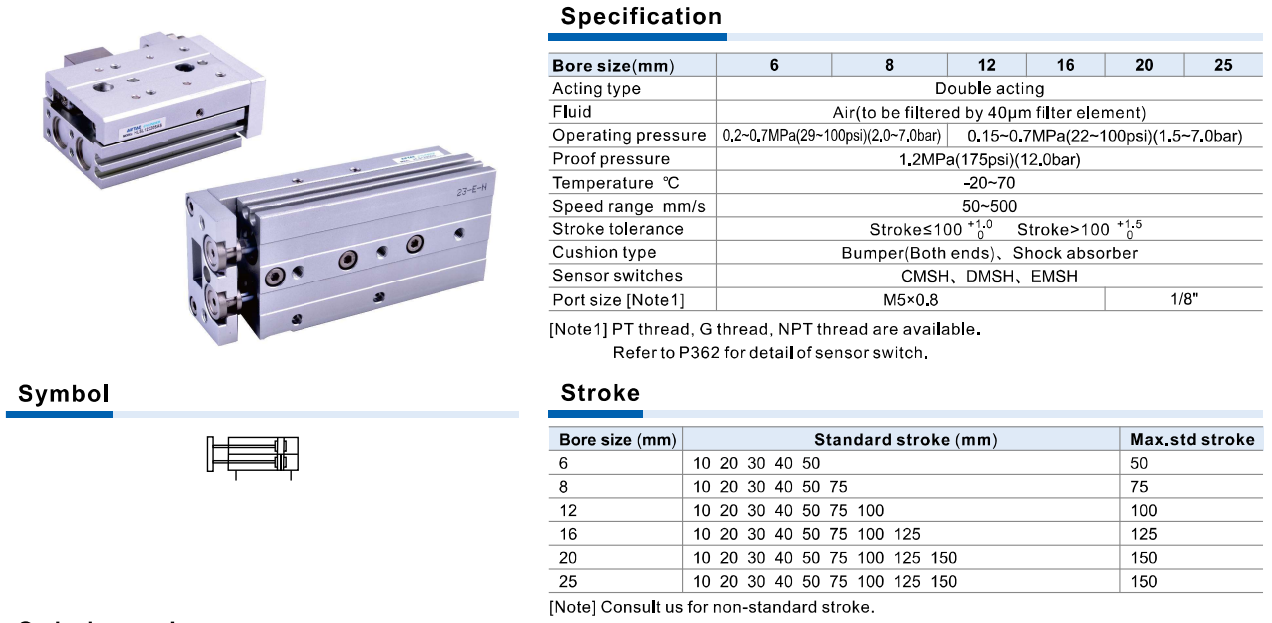

The Airtac HLS / HLSL slide table cylinder features a cross roller guide structure that provides high rigidity, heavy load capacity, and precise non-rotating linear motion. With a dual rod design, compact construction, and flexible mounting options, the HLS/HLSL series is ideal for high-precision automation and assembly applications.

- Airtac HLS6

- HLS6x10

- HLS6x20

- HLS6x30

- HLS6x40

- HLS6x50

- HLS8

- HLS8x10

- HLS8x20

- HLS8x30

- HLS8x40

- HLS8x50

- HLS8x75

- HLS12

- HLS12x10

- HLS12x20

- HLS12x30

- HLS12x40

- HLS12x50

- HLS12x75

- HLS12x100

- HLS16

- HLS16x10

- HLS16x20

- HLS16x30

- HLS16x40

- HLS16x50

- HLS16x75

- HLS16x100

- HLS16x125

- HLS20

- HLS20x10

- HLS20x20

- HLS20x30

- HLS20x40

- HLS20x50

- HLS20x75

- HLS20x100

- HLS20x125

- HLS20x150

- HLS25

- HLS25x10

- HLS25x20

- HLS25x30

- HLS25x40

- HLS25x50

- HLS25x75

- HLS25x100

- HLS25x125

- HLS25x150

- HLSL6

- HLSL6x10

- HLSL6x20

- HLSL6x30

- HLSL6x40

- HLSL6x50

- HLSL8

- HLSL8x10

- HLSL8x20

- HLSL8x30

- HLSL8x40

- HLSL8x50

- HLSL8x75

- HLSL12

- HLSL12x10

- HLSL12x20

- HLSL12x30

- HLSL12x40

- HLSL12x50

- HLSL12x75

- HLSL12x100

- HLSL16

- HLSL16x10

- HLSL16x20

- HLSL16x30

- HLSL16x40

- HLSL16x50

- HLSL16x75

- HLSL16x100

- HLSL16x125

- HLSL20

- HLSL20x10

- HLSL20x20

- HLSL20x30

- HLSL20x40

- HLSL20x50

- HLSL20x75

- HLSL20x100

- HLSL20x125

- HLSL20x150

- HLSL25

- HLSL25x10

- HLSL25x20

- HLSL25x30

- HLSL25x40

- HLSL25x50

- HLSL25x75

- HLSL25x100

- HLSL25x125

- HLSL25x150

- airtac hls hlsl slide table cylinder

- cross roller slide table cylinder

- high rigidity pneumatic slide

- precision linear slide cylinder

- industrial pneumatic slide unit

Design file download links:

Other fileOther filePDF fileDescription

Specification:

Product Overview

The Airtac HLS / HLSL slide table cylinder is a cross roller type pneumatic slide unit designed for applications that demand extreme precision, high rigidity, and heavy load capacity. Its advanced guide structure ensures smooth, stable, and non-rotating linear motion with excellent positioning repeatability.

Key Features & Characteristics

- Integrated cross roller guide system for superior rigidity, accuracy, and load handling

- Dual rod piston structure that significantly increases thrust and operational stability

- Available in two models:

- HLS: standard type

- HLSL: symmetrical type for balanced loading and flexible installation

- Floating joint design reduces additional torque on piston rods, extending service life

- Flexible installation with three cylinder mounting directions

- Two workpiece mounting directions to suit various fixture designs

- Magnetic sensor slots around the cylinder body for easy stroke detection

- Optional bumper or shock absorber for impact absorption at stroke ends

- Wide bore size range 6, 8, 12, 16, 20, 25 mm for different load and stroke requirements

Applications

- Industrial automation systems

- Precision mechanical and electronic assembly machines

- High-load sliding, pushing, and positioning mechanisms

- Pick-and-place systems and industrial robotics

- Applications requiring high rigidity, precise non-rotating motion, and reliable long-term performance