- Home/

- Category/

- Airtac Pneumatic/

- Slide Table Cylinders Airtac

/ Airtac HGS Slide Table Pneumatic Cylinder – High Precision Linear Motion

Airtac HGS Slide Table Pneumatic Cylinder – High Precision Linear Motion

Price:Contact Jade M-Tech

Category: Slide Table Cylinders Airtac

SKU: HGS

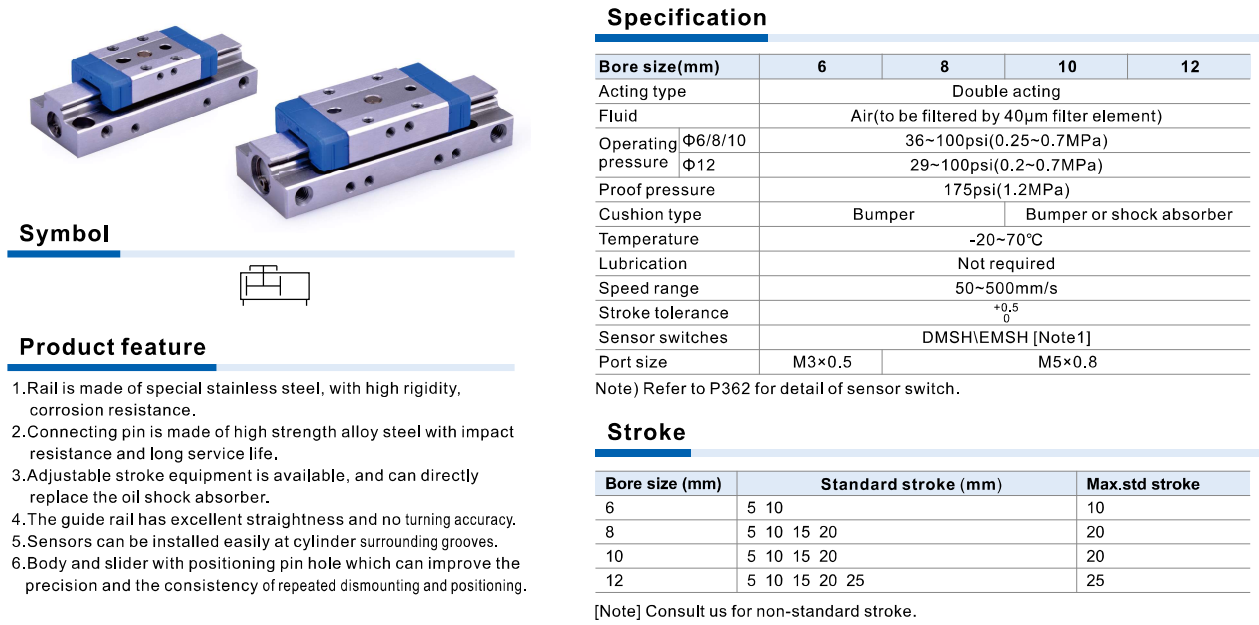

The Airtac HGS slide table cylinder is a compact double-acting pneumatic slide unit with an integrated precision guide rail for smooth and stable linear motion. Designed for high accuracy and repeatability, the HGS series is ideal for automation, assembly, and positioning applications requiring reliable sliding movement.

HGS Series Models & Sizes:

- Airtac HGS6

- HGS6x5

- HGS6x10

- HGS8

- HGS8x5

- HGS8x10

- HGS8x15

- HGS8x20

- HGS10

- HGS10x5

- HGS10x10

- HGS10x15

- HGS10x20

- HGS12

- HGS12x5

- HGS12x10

- HGS12x15

- HGS12x20

- HGS12x25

- airtac hgs slide table cylinder

- pneumatic slide table

- linear slide pneumatic cylinder

- precision slide table cylinder

- industrial pneumatic slide unit

Show more

Design file download links:

PDF fileRAR fileOther file** If you are using Google Chrome, please copy the download link and paste it into a new tab to download the 3D file (For support, please contact hotline: +84 935 136 236).

Description

Specification:

Product Overview

The Airtac HGS slide table cylinder is a compact pneumatic slide unit that integrates a precision guide rail and sliding table to provide smooth, stable, and non-rotating linear motion. Operating in double-acting mode, it is ideal for applications requiring high accuracy, repeatability, and space-saving design.

Key Features & Characteristics

- Integrated slide table design for smooth and stable linear movement

- Precision stainless steel guide rail with high rigidity and corrosion resistance

- High-strength alloy steel connecting pin for impact resistance and long service life

- Excellent straightness and anti-rotation performance during sliding motion

- Easy installation of magnetic sensors via surrounding grooves

- Optional bumper or shock absorber to absorb impact at stroke ends

- Maintenance-free operation with no lubrication required

Applications

- Industrial automation systems

- Electronic assembly machines

- Precision positioning and sliding mechanisms

- Pick-and-place equipment

- Production lines requiring accurate and repeatable linear sliding motion