- Home/

- Category/

- Airtac Pneumatic/

- Mini Cylinders Airtac

/ AirTAC MG Series Mini Pneumatic Cylinder – Single & Double Acting

AirTAC MG Series Mini Pneumatic Cylinder – Single & Double Acting

Price:Contact Jade M-Tech

Category: Mini Cylinders Airtac

SKU: MG / MGC

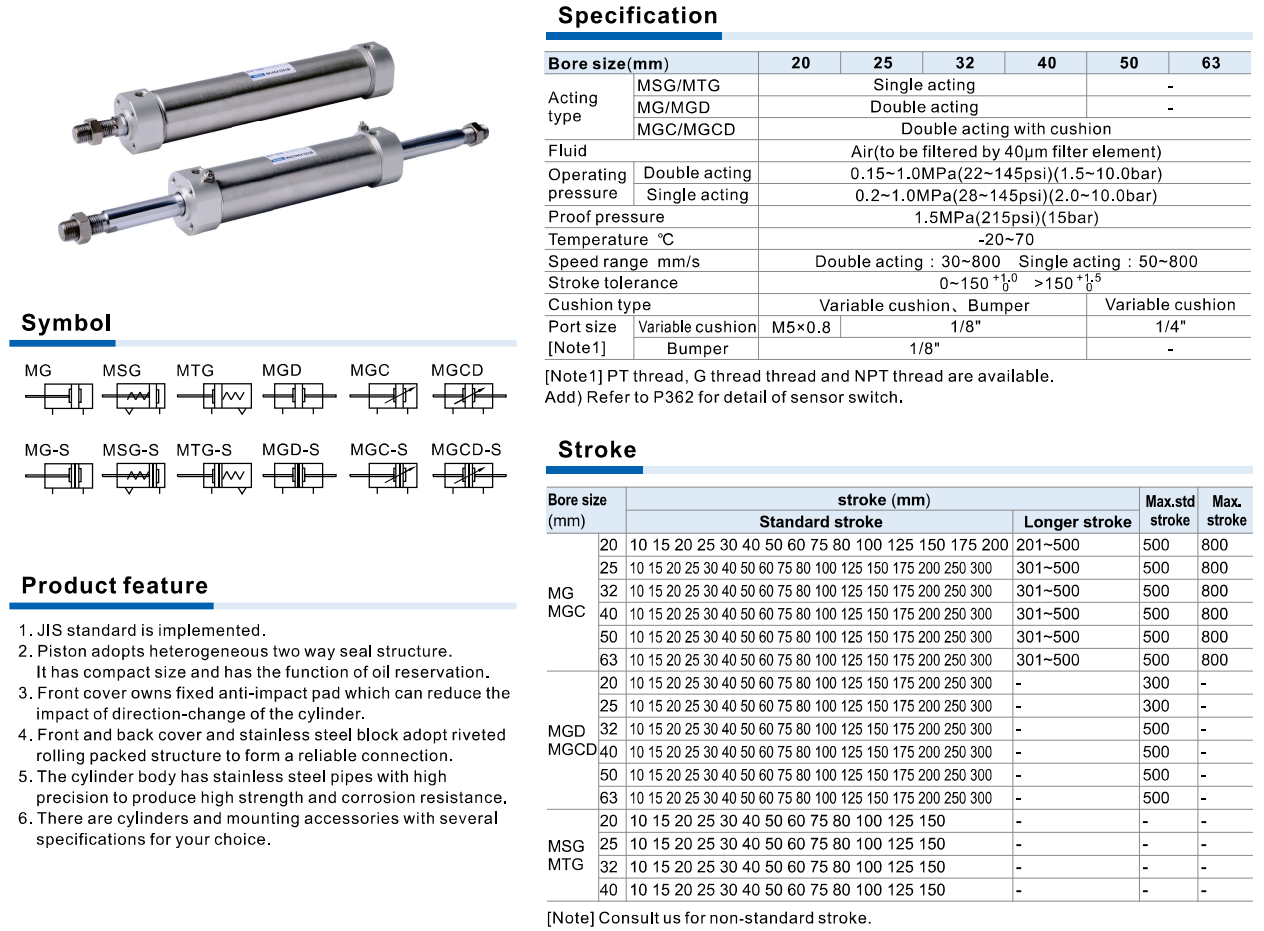

AirTAC MG Series mini pneumatic cylinders feature a compact JIS-standard design with single-acting and double-acting options. With high durability, smooth operation, and stable performance, they are ideal for automation systems, industrial machinery, and precision pneumatic applications.

MG / MGC Series Models & Sizes:

- Series

- MG

- MGD

- MGC

- MGCD

- MSG

- MTG

- MG20

- MG25

- MG32

- MG40

- MG50

- MG63

- MGD20

- MGD25

- MGD32

- MGD40

- MGD50

- MGD63

- MGC20

- MGC25

- MGC32

- MGC40

- MGC50

- MGC63

- MGCD20

- MGCD25

- MGCD32

- MGCD40

- MGCD50

- MGCD63

- MSG20

- MSG25

- MSG32

- MSG40

- MTG20

- MTG25

- MTG32

- MTG40

- MG20x10

- MG20x20

- MG20x30

- MG20x50

- MG20x100

- MG25x10

- MG25x20

- MG25x50

- MG25x100

- MG32x20

- MG32x50

- MG32x100

- MG40x20

- MG40x50

- MG40x100

- MG50x20

- MG50x50

- MG50x100

- MG63x20

- MG63x50

- MG63x100

- MGD20x10

- MGD20x20

- MGD20x50

- MGD20x100

- MGD25x20

- MGD25x50

- MGD25x100

- MGD32x20

- MGD32x50

- MGD32x100

- MGD40x20

- MGD40x50

- MGD40x100

- MGD50x20

- MGD50x50

- MGD50x100

- MGD63x20

- MGD63x50

- MGD63x100

- MGC20x10

- MGC20x20

- MGC20x50

- MGC20x100

- MGC25x20

- MGC25x50

- MGC25x100

- MGC32x20

- MGC32x50

- MGC32x100

- MGC40x20

- MGC40x50

- MGC40x100

- MGC50x20

- MGC50x50

- MGC50x100

- MGC63x20

- MGC63x50

- MGC63x100

- MGCD20x10

- MGCD20x20

- MGCD20x50

- MGCD20x100

- MGCD25x20

- MGCD25x50

- MGCD25x100

- MGCD32x20

- MGCD32x50

- MGCD32x100

- MGCD40x20

- MGCD40x50

- MGCD40x100

- MGCD50x20

- MGCD50x50

- MGCD50x100

- MGCD63x20

- MGCD63x50

- MGCD63x100

- MSG20x10

- MSG20x20

- MSG20x50

- MSG20x100

- MSG25x20

- MSG25x50

- MSG25x100

- MSG32x20

- MSG32x50

- MSG32x100

- MSG40x20

- MSG40x50

- MSG40x100

- MTG20x10

- MTG20x20

- MTG20x50

- MTG20x100

- MTG25x20

- MTG25x50

- MTG25x100

- MTG32x20

- MTG32x50

- MTG32x100

- MTG40x20

- MTG40x50

- MTG40x100

- airtac MG pneumatic cylinder

- mini pneumatic cylinder

- compact air cylinder

- double acting air cylinder

- industrial automation cylinder

Show more

Design file download links:

PDF fileOther file** If you are using Google Chrome, please copy the download link and paste it into a new tab to download the 3D file (For support, please contact hotline: +84 935 136 236).

Description

Specification:

Overview of AirTAC MG Series Mini Pneumatic Cylinder

The AirTAC MG Series mini pneumatic cylinder is a JIS-standard air cylinder featuring a compact round stainless-steel design, widely used in industrial automation systems. The series includes single-acting, double-acting, and cushioned double-acting types, offering flexible solutions for various industrial applications.

Features and characteristics based on the product image

- Compact round body design, ideal for limited installation space

- Stainless steel cylinder tube with excellent corrosion resistance

- Piston equipped with dual-direction seals for stable and reliable operation

- Available versions: MSG, MTG (single acting); MG, MGD (double acting); MGC, MGCD (double acting with cushion)

- Bore size range from 20 to 63 mm with multiple stroke options

- Optional adjustable cushioning to reduce impact at end positions

- Long service life under continuous industrial operation

Basic technical specifications

- Working medium: Filtered compressed air

- Maximum operating pressure: 1.0 MPa

- Operating temperature: -20 to 70°C

- Thread type: PT / G / NPT

Applications of AirTAC MG Series pneumatic cylinders

- Industrial automation production lines

- Packaging, filling, and labeling machines

- Pushing, clamping, lifting mechanisms

- Mechanical engineering and electronics industries

- Equipment requiring high precision and durability