- Home/

- Category/

- Airtac Pneumatic/

- Multi-mount Cylinders Airtac

/ Airtac MD series cylinders

Airtac MD series cylinders

General introduction of AIRTAC MD pneumatic cylinders AIRTAC MD pneumatic cylinders are a reliable choice for applications in the pneumatic control industry. AIRTAC, one of the leading manufacturers of pneumatic equipment, has created this product line with a focus on quality and performance. • Designed to meet a wide range of application requirements, AIRTAC MD cylinders are made from high-quality materials, ensuring durability and stability in harsh working environments. With a variety of sizes and types, from standard cylinders to special versions, this product is flexible and can be customized to suit the specific needs of each application. • With advanced technology and quality manufacturing processes, AIRTAC MD cylinders ensure high performance and reliability in use. Smart and convenient design makes installation and operation easier, minimizing the time and effort required for maintenance and repair. With these outstanding advantages, AIRTAC MD pneumatic cylinders have been widely used in manufacturing industries, from automation to machinery manufacturing. This is a reliable and effective solution for pneumatic applications that require stability and quality.

- #cylinder #Airtac_MD_cylinder #MD #Pneumatic_cylinder #Airtac

Description

Product Feature of Airtac MD series cylinders

- Manufactured by our enterprise.

- There are several ways to fix the cylinder and it is convenient to install and use.

- Several cylinders can be assembled together to effectively save the installation space.

- The guide precision of piston rod is high and no additional lubricant is needed.

- Cylinders of various specifications are optional.

- The seal material with high temperature resistance is adopted to guarantee the normal operation of cylinder at 150℃(Option).

Installation and application of Airtac MD series cylinders

- When load changes in the work, the cylinder with abundant output capacity shall be selected.

- Relative cylinder with high temperature resistance or corrosion resistance shall be chosen under the condition of high temperature or corrosion;

- Necessary protection measure shall be taken in the environment with higher humidity, much dust or water drops, oil dust and welding dregs.

- Dirty substances in the pipe must be cleared away before cylinder is connected with pipeline to prevent the entrance of particles into the cylinder.

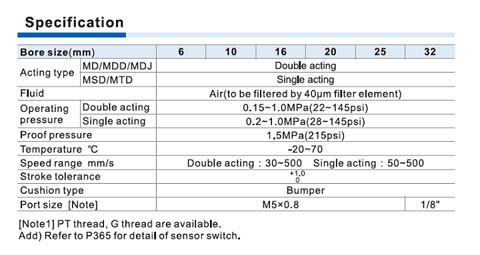

- The medium used by cylinder shall be filtered to 40µm or below.

- As both of the front cover and piston of the cylinder are short, typically too large stroke can not be selected.

- Anti-freezing measure shall be adopted under low temperature environment to prevent moisture freezing.

- The cylinder shall avoid the influence of side load in operation maintain the normal work of cylinder and extend the service life.

- If the cylinder is dismantled and stored for a long time, pay attention to conduct anti-rust treatment to the surface. Anti-dust caps shall be added in air inlet and outlet ports.

Functions of AIRTAC MD pneumatic cylinders

The main function of AIRTAC MD pneumatic cylinders is to move various mechanisms or jobs by using compressed air pressure to generate pushing or pulling force. Here are some specific functions of AIRTAC MD pneumatic cylinders:

- Converting pneumatic energy into linear motion: When compressed air is fed into the cylinder through the air supply ports, it will act on the piston, creating a pushing force that moves the piston and piston shaft in the desired direction. This movement can be used to perform operations such as pushing, pulling, clamping, etc.

- Providing force: The pushing force of the AIRTAC MD pneumatic cylinder depends on the supplied compressed air pressure and the cross-sectional area of the piston. The cylinder can generate a large pushing force, enough to perform heavy-duty work.

- Position and speed control: The AIRTAC MD pneumatic cylinder can be controlled by a pneumatic valve to accurately adjust the position and speed of the piston. This makes the cylinder suitable for a wide range of applications.

- Motion repeatability: The AIRTAC MD pneumatic cylinder can perform repetitive motions accurately and consistently. This helps increase efficiency and productivity in manufacturing.

In short, the AIRTAC MD pneumatic cylinder functions to provide power and linear motion, making it an important tool in many industrial and automation applications.

Applications of AIRTAC MD Pneumatic Cylinders

AIRTAC MD pneumatic cylinders are widely used in various industries and applications due to their versatility, performance, and reliability. Here are some common applications of this cylinder:

- Automation industry: AIRTAC MD cylinders are commonly used in automation systems to control the movement of mechanisms, machines, and robots. They are used to lift, push, pull, rotate, and perform precise tasks in automated manufacturing processes.

- Industrial machinery and equipment: In industrial equipment and machinery, AIRTAC MD cylinders are used to perform functions such as clamping, compressing, pressing, and moving parts and tools in the manufacturing process.

- Medical equipment: In the medical industry, pneumatic cylinders are used in medical equipment such as surgical tables, lift chairs, and diagnostic imaging equipment to control moving parts and positions. Machining and manufacturing: AIRTAC MD cylinders are used in machining and manufacturing equipment to perform tasks such as drilling, cutting, grinding and bending, improving the efficiency and accuracy of machining processes.

- Food and packaging industry: In the food and packaging industry, AIRTAC MD cylinders are used to control packaging equipment, bakery machines, bottling machines and other processes. Automotive industry: In automotive manufacturing, pneumatic cylinders are used in equipment and systems such as suspension, brakes, doors and trunks to perform travel and control functions.

In short, AIRTAC MD pneumatic cylinders are an important component in many different industrial and automation applications, improving the efficiency, accuracy and reliability of manufacturing and control processes.

.png&w=1200&q=75)

.png&w=1200&q=75)

.png&w=640&q=75)

.png&w=640&q=75)

.png&w=640&q=75)