- Home/

- Category/

- Airtac Pneumatic/

- Mini Cylinders Airtac

/ Airtac MA Series Mini Pneumatic Cylinder – Compact Stainless Steel Air Cylinder

Airtac MA Series Mini Pneumatic Cylinder – Compact Stainless Steel Air Cylinder

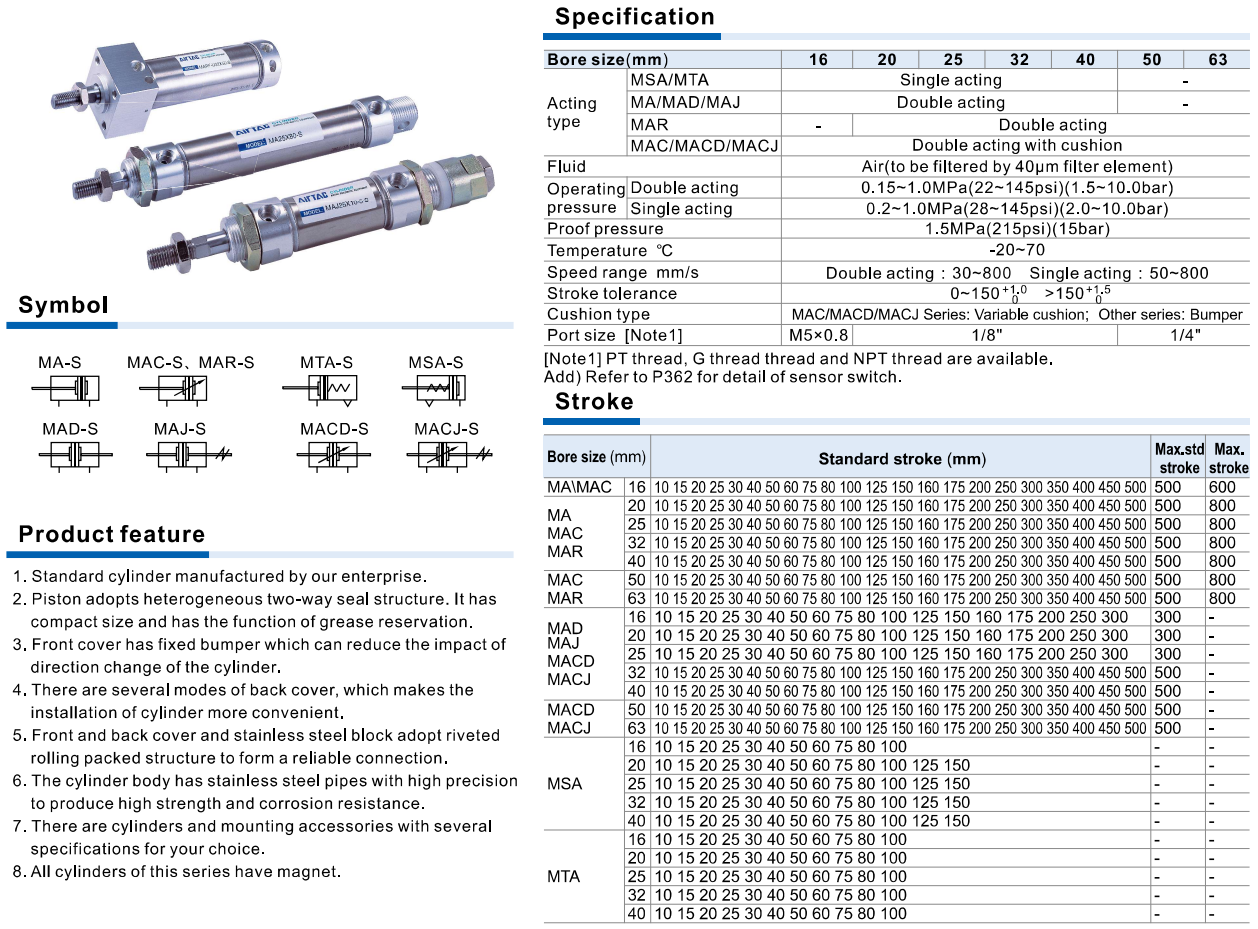

The Airtac MA Series pneumatic cylinder is a compact mini air cylinder featuring a stainless steel body, available in single acting, double acting and double acting with cushion types. With stable performance and flexible installation, it is ideal for automation equipment, production lines and precision machinery.

- Airtac MA

- MAC

- MAR

- MAD

- MAJ

- MACD

- MACJ

- MSA

- MTA

- MA16

- MA20

- MA25

- MA32

- MA40

- MA50

- MA63

- MAC16

- MAC20

- MAC25

- MAC32

- MAC40

- MAC50

- MAC63

- MAR16

- MAR20

- MAR25

- MAR32

- MAR40

- MAR50

- MAR63

- MAD16

- MAD20

- MAD25

- MAD32

- MAD40

- MAJ16

- MAJ20

- MAJ25

- MAJ32

- MAJ40

- MACD16

- MACD20

- MACD25

- MACD32

- MACD40

- MACD50

- MACD63

- MACJ16

- MACJ20

- MACJ25

- MACJ32

- MACJ40

- MACJ50

- MACJ63

- MSA16

- MSA20

- MSA25

- MSA32

- MSA40

- MTA16

- MTA20

- MTA25

- MTA32

- MTA40

- MA16x10

- MA16x20

- MA16x30

- MA16x40

- MA16x50

- MA16x75

- MA16x100

- MA20x10

- MA20x20

- MA20x30

- MA20x40

- MA20x50

- MA20x75

- MA20x100

- MA20x125

- MA20x150

- MA20x200

- MA25x10

- MA25x20

- MA25x30

- MA25x40

- MA25x50

- MA25x75

- MA25x100

- MA25x125

- MA25x150

- MA25x200

- MA32x10

- MA32x20

- MA32x30

- MA32x40

- MA32x50

- MA32x75

- MA32x100

- MA32x125

- MA32x150

- MA32x200

- MA40x10

- MA40x20

- MA40x30

- MA40x40

- MA40x50

- MA40x75

- MA40x100

- MA40x125

- MA40x150

- MA40x200

- MA50x10

- MA50x20

- MA50x30

- MA50x40

- MA50x50

- MA50x75

- MA50x100

- MA50x125

- MA50x150

- MA50x200

- MA63x10

- MA63x20

- MA63x30

- MA63x40

- MA63x50

- MA63x75

- MA63x100

- MA63x125

- MA63x150

- MA63x200

- mini pneumatic cylinder

- Airtac MA series

- stainless steel mini cylinder

- magnetic air cylinder

- compact pneumatic cylinder

Design file download links:

PDF fileRAR fileOther fileDescription

Specification:

What Is Airtac MA Series Mini Pneumatic Cylinder?

The Airtac MA Series pneumatic cylinder is a round body stainless steel mini air cylinder, designed for automation systems that require compact size, high durability and stable performance. The MA Series is available in single acting, double acting and double acting with cushion, making it suitable for a wide range of industrial applications.

Key Features Of Airtac MA Series Pneumatic Cylinder

- Stainless steel cylinder body, providing excellent corrosion resistance

- Compact round body design, ideal for space-limited installations

- Two-way piston seal structure, ensuring good air tightness and long service life

- Reinforced front and rear covers, improving strength under working pressure

- Multiple series options: MA, MAC, MAR, MAD, MAJ, MACD, MACJ, MSA, MTA for flexible selection

- Cushioned versions available, reducing end-stroke impact and improving smooth operation

- Fast response speed, suitable for high-frequency working conditions

- Wide bore size range from 16mm to 63mm, with various standard stroke options

Typical Technical Specifications

- Operation type: Single acting / Double acting / Double acting with cushion

- Bore size: 16, 20, 25, 32, 40, 50, 63 mm

- Working pressure: 0.15 – 1.0 MPa

- Working temperature: -20°C to 70°C

- Standard stroke: 10mm to 500mm (depending on model)

- Thread type: PT, G, NPT available

Applications Of Airtac MA Series Mini Cylinder

- Industrial automation systems

- Clamping, pushing and positioning mechanisms

- Packaging, filling and assembly machines

- Precision machinery and electronics industry

- Production lines requiring compact and durable air cylinders