- Home/

- Category/

- Chrome-plated shaft, Shaft with base, Bearing/

- Linear brearing

/ Linear bearing SCEL-UU SCEL-AJ-UU

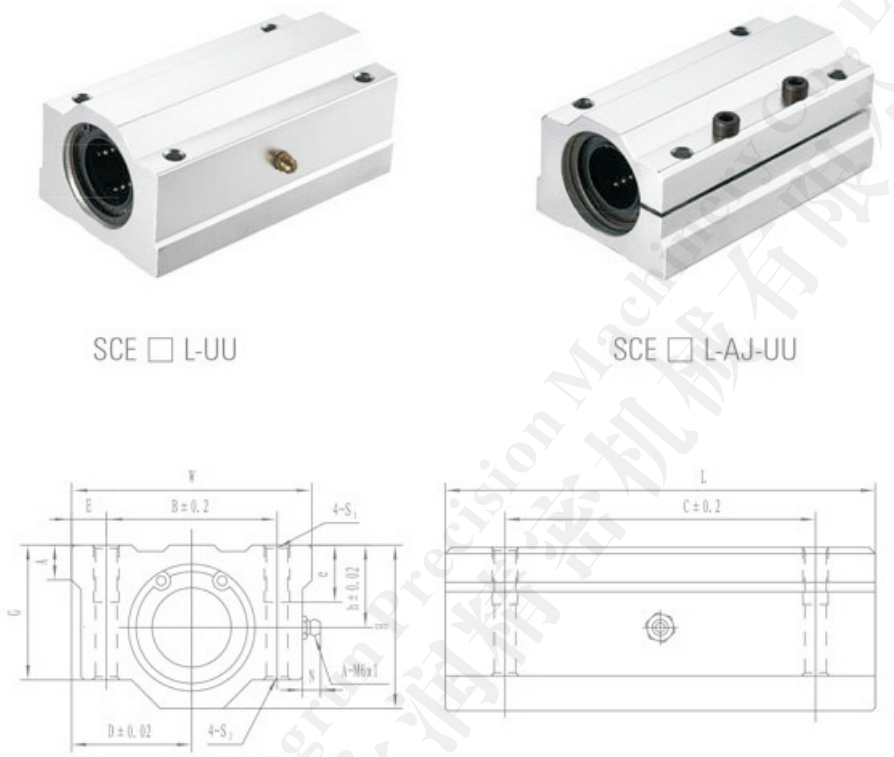

Linear bearing SCEL-UU SCEL-AJ-UU

Sliding bearings are corrosion and rust resistant, simply designed for easy disassembly and use. This is a very important part in mechanical transmission, composed of inner and outer rings and many distinct features. Jadem-tech is proud to be the place to provide genuine, high-class sliding bearings with the best prices in the market.

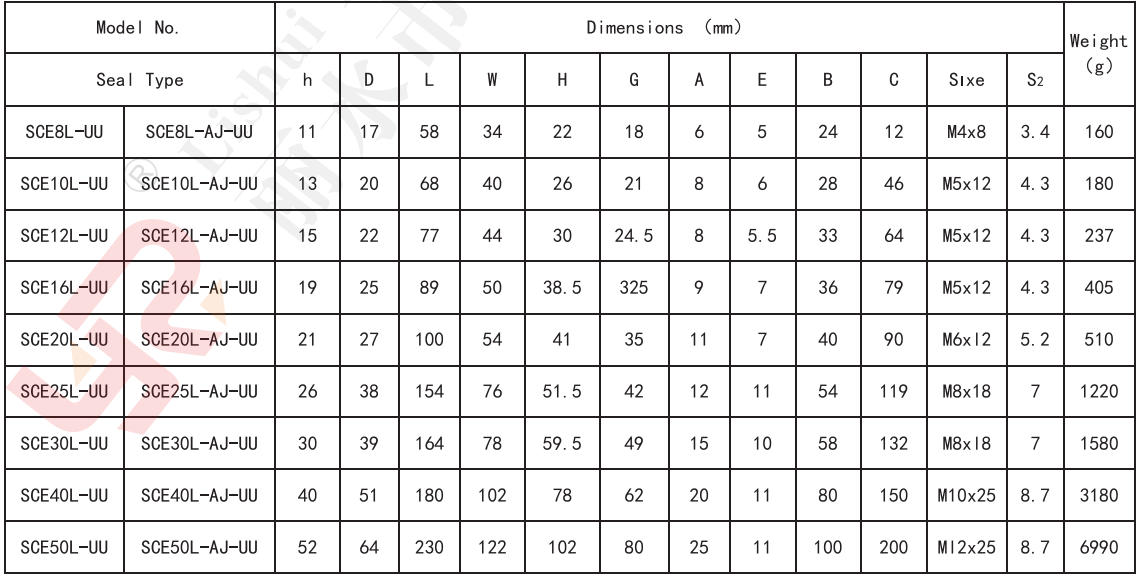

- Vòng bi trượt SCE8LUU

- SCE10LUU

- SCE12LUU

- SCE16LUU

- SCE20LUU

- SCE25LUU

- SCE30LUU

- SCE40LUU

- SCE50LUU

- SCE8LAJUU

- SCE10LAJUU

- SCE12LAJUU

- SCE16LAJUU

- SCE20LAJUU

- SCE25LAJUU

- SCE30LAJUU

- SCE40LAJUU

- SCE50LAJUU

Description

Specification:

Feature:

Sliding bearings are special bearings, the rollers move continuously in the bearing tube. This form of bearing is widely used and popular in many areas of industry. It is often applied in automatic packaging cutting machines, paper cutting machines, in agriculture, transportation and construction.

Structure of sliding bearing

Bearing roller: This part determines the shape of the rod and ball.

Cage: This is an indispensable part in the bearing, it has the effect of fixing the position on the groove of the rollers to reduce the number of rollers and prevent them from sliding out.

Seal: Depending on the characteristics of each bearing, this part may or may not be fixed. They are often used in circular sliding bearings, drums, etc., with the purpose of helping to block dirt and retain lubricating grease in the bearing of the device.

Inner ring, outer ring: These are the two basic parts that make the bearing have a complete structure in which the outer ring is fixed to the housing and the inner ring is fixed to the machine shaft.

Similar to many other bearings, sliding bearings are also composed of an outer ring, an inner ring, a roller, a cage and a seal.

- Outer ring: fixed installation with the case.

- Inner ring: fixed to the machine shaft. Look for bearings whose inner face has a spherical groove or a tapered cylinder.

- Rollers: There are many types of rollers corresponding to different shapes such as spherical rollers, cylindrical rollers, drum rollers, needle rollers, etc.

- Cage: has the role of positioning the ball at fixed distances between the ball tracks. Usually it is made from steel, copper, plastic.

- Seal: usually ball bearings, spherical roller bearings or needle bearings have seals to trap grease and prevent dirt.

Outstanding advantages

Bearing capacity, load bearing with radial feature.

Made of high-grade steel and iron with corrosion resistance, rust resistance and durable operation, long service life. Therefore, it can be applied effectively even in harsh environments.

Position the axis, position the part accurately, make sure the part does not leave the working position. Ensure operational productivity, save maintenance and repair costs.

High applicability.

Perfect hardness and durability.

The role of ball bearings

As we shared in the first part, this is an important part in the mechanical industry because they have important functions such as:

- Increased durability for engines and transmissions: With the ability to support as well as bear forces in many different directions, the product has the ability to help the gearbox, the engine of the machinery and equipment more durable during use.

- Minimize friction: This is a major role of this product line because during operation, friction will cause obstruction and degrade the operation of machine parts and reduce working productivity. And with the appearance of ball bearings, it reduces that friction and helps machines work better, faster, and more efficiently.

- Positioning axis, rotating details: This part has the effect of positioning the rotating parts, the fixed axis is not far from the operating position.

- Minimize noise when operating.: Thanks to the appearance of sliding ball bearings, all noise during operation is significantly reduced while providing quieter, smoother and softer operations.