- Home/

- Category/

- Riveting machine, Magnetic Drilling Machine Atoli/

- Riveting machine Machine Atoli

/ Pneumatic Riveting Machine TC-106K

Pneumatic Riveting Machine TC-106K

Price:Contact Jade M-Tech

Category: Riveting machine Machine Atoli

SKU: TC-106K

Riveting machines in general or pneumatic riveting machines in particular are mechanical machines that use a controlled pneumatic system to rivet metal parts called rivets, creating connections between two or more parts. together

TC-106K Series Models & Sizes:

- Pneumatic Riveting Machine TC-106K

Show more

Description

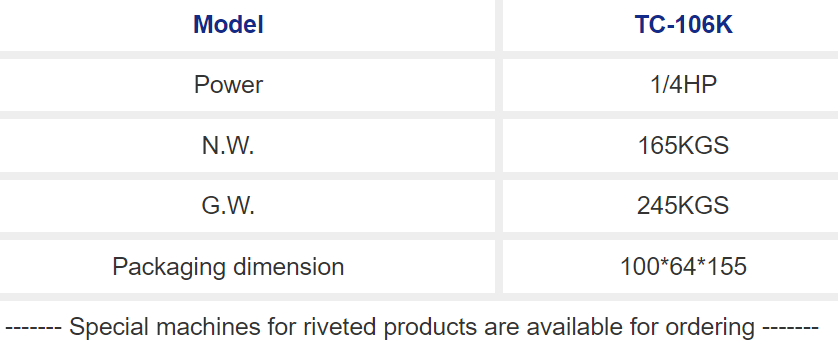

Technical parameters of pneumatic riveting machine:

Outstanding features of pneumatic riveting machine

- The pneumatic riveting machine is a standard, pneumatically controlled riveting machine designed as a workbench type. This riveting machine model is specialized for riveting solid iron or steel rivets. This riveting machine model is specialized for riveting solid iron or steel rivets.

- Basic adjustment: The orbital head can be raised and lowered.

- Micro-adjustment: The screw cap is equipped with an index scale used for micro-adjustment.

- The counter on the control panel can be used to count the number of scattered pieces.

- Outstanding features of the pneumatic riveting machine

- This is the newest forming and riveting process, instead of spinning, punching, pressing, welding, turning, riveting results in a very smooth metal surface, it will greatly increase output and save electricity.

- Increase output greatly and save labor costs.

- The good quality of all parts on this machine ensures a smooth workpiece surface and the stability of the machining process.

- Double air regulators can be used to control the riveting speed effectively.

- The air duct is equipped with an air filter to prevent moisture.

- Acceptable for hollow rivets, semi-tubular rivets, solid rivets.

- Easy operation and operation.

- Vertical style, desk design, helps workers relax and feel comfortable.

- Driven by compressed air.

- Take small area, easy to maintain, very easy to replace worn parts by workers.

- High yield and economic price.

- Safety devices to prevent injury to people