- Home/

- Category/

- Riveting machine, Magnetic Drilling Machine Atoli/

- Portable Magnetic Drilling Machine

/ Magnetic Stand For Drill ATT-35

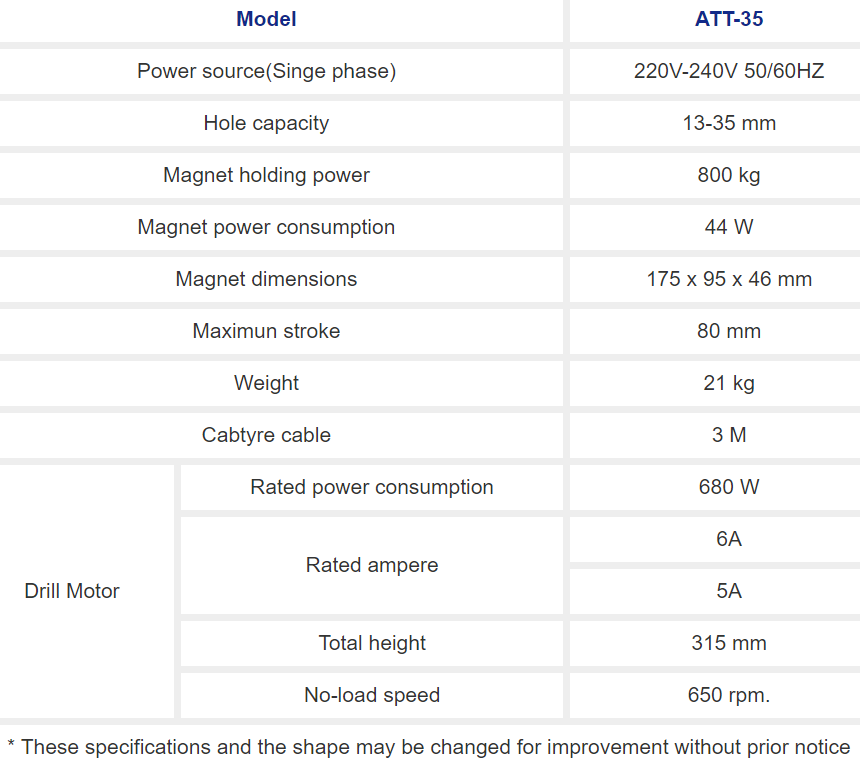

Magnetic Stand For Drill ATT-35

To meet the needs of drilling and cutting hard materials, as well as performing operations in special positions that conventional drilling machines cannot perform. Magnetic drills seem to meet many different requirements. To better understand magnetic drilling machines, please refer to the article below with .

- Magnetic Stand For Drill ATT-35

Description

Specifications:

WHAT IS A MAGNETIC DRILL?

A magnetic drill is a device in a line of drilling machines with a special design, the base is equipped with a magnetic magnet that can automatically connect to the plane you need to drill. Magnetic base with strong binding force, so even if the surface to be drilled is in difficult positions, it will be easily fixed and performed.

The magnetic base that supports the machine is fixed, minimizing the machine's vibration, shaking or the drill bit being misaligned while operating. Thanks to the magnetic force of the base, the magnetic drill can operate in any direction such as horizontal, vertical, inclined or even upside down.

Magnetic drills are frequently used to chamfer holes, ratchet or process many different types of metal.

With a flexible design for movement, light weight and many outstanding features, magnetic drilling machines seem to be indispensable equipment in fields such as shipbuilding, drilling rigs, bridges and roads, or other activities. on high hardness iron and steel materials that common drills cannot perform

BASIC STRUCTURE OF MAGNETIC DRILLING MACHINE

- The machine body has a handle to help users easily move it to different working positions.

- The starting part includes a regulator for pressure and direction of rotation of the motor.

- Shelf.

- The power cord provides power for machine operation.

- Rotating motor part.

- The engine part is stationary.

- The cooling system is installed with a fan that has the function of cooling the engine.

- Transmission gear

- The drill shaft has a drill clamp attached

- Shaft bearings

- Drill shaft

- Magnetic base

WORKING PRINCIPLE OF MAGNETIC DRILLING MACHINE

Magnetic drills operate on the principle of using momentum to create a vibration between the drill head and the cutting surface. The drill head is pushed into the material and rotated, creating a hole in the material. Drill bits can come in many different sizes and shapes to suit a variety of materials.

HOW TO CHOOSE A MAGNETIC DRILLING MACHINE?

With the current market of magnetic drilling machines with a variety of designs and prices, it is important to determine your needs in advance to find a suitable and quality magnetic drilling machine. Normally, to choose a magnetic drill, you can refer to the following criteria:

Choose according to your needs

- Determine your usage needs in advance so you can choose a suitable magnetic drill. Currently, magnetic drills often have the function of drilling, cutting or tapping. If your needs are just drilling or cutting or tapping, you should choose a machine with the right functions to save costs.

- If your usage needs have more than 2 functions, you should consider a multi-function machine. Besides, you can also refer to the brands just mentioned to choose the most suitable machine.

Select by origin

- Drilling machines originating from Taiwan or China are usually cheap machines that are easy to find and buy. However, the machine's working capacity is not too large, suitable for jobs that do not require drilling too many holes in one session and do not require absolute accuracy.

- Magnetic drilling machines from Germany and the US have good quality, reasonable prices, can be invested, working capacity is also relatively stable, especially replacement parts are easy to find on the market.

- Machines from Japan have outstanding quality. However, the price is high and replacement parts are difficult to find

Choose according to processing material

- Normally, each device will have a note on the appropriate processing materials to ensure the accuracy of the machine.

- Users need to refer to and use the right materials to ensure the longevity of the machine.

- For example, on equipment designed to drill with medium hardness steel, users drilling with high hardness steel will reduce accuracy or may not be able to operate.

8 NOTES WHEN USING THE MAGNETIC DRILLING MACHINE

To ensure the machine operates well, keep the machine's longevity high, and most importantly, ensure user safety, the following issues should be noted when using the machine:

- The working surface of the machine needs to be flat, dry, and free of dust or debris that prevents the connection between the machine and the material. If the magnetic drill is securely attached to the device, the working process will be effective and accurate.

- Check the machine's parts before use to ensure there are no unusual signs that affect the use process.

- You should read the user manual carefully, because each machine will have different uses. Learning carefully will help reduce the risk of risks and help use the machine most effectively.

- If you want to adjust the functions of the machine, you must do it when the machine is turned off, absolutely do not adjust while the machine is still in operating mode.

- Always wear protective clothing when using to ensure safety.

- Do not use your hands to clean the chip.

- You should wait for the machine to stop completely before putting it down or moving it to another location, because it will cause unsafety for the user and easily break the drill bit.

- Replace the drill bit tip when it no longer has the necessary grip to help the drill operate more efficiently and productively.