- Home/

- Category/

- Skon pressure gauge/

- Skon pressure gauge

/ All Stainless Steel Filled Pressure Gauges 422.23

All Stainless Steel Filled Pressure Gauges 422.23

A pressure gauge (also known as a manometer) is one of the devices that appears frequently in each of our daily lives. We can easily see pressure gauges from car repair shops to factories. Pressure watches have almost the same structure and design as other types of time indicators, but they are often used to measure pressure. In fact, there are two common types of pressure gauges: mechanical pressure gauges and electronic pressure gauges.

- All Stainless Steel Filled Pressure Gauges 422.23

Description

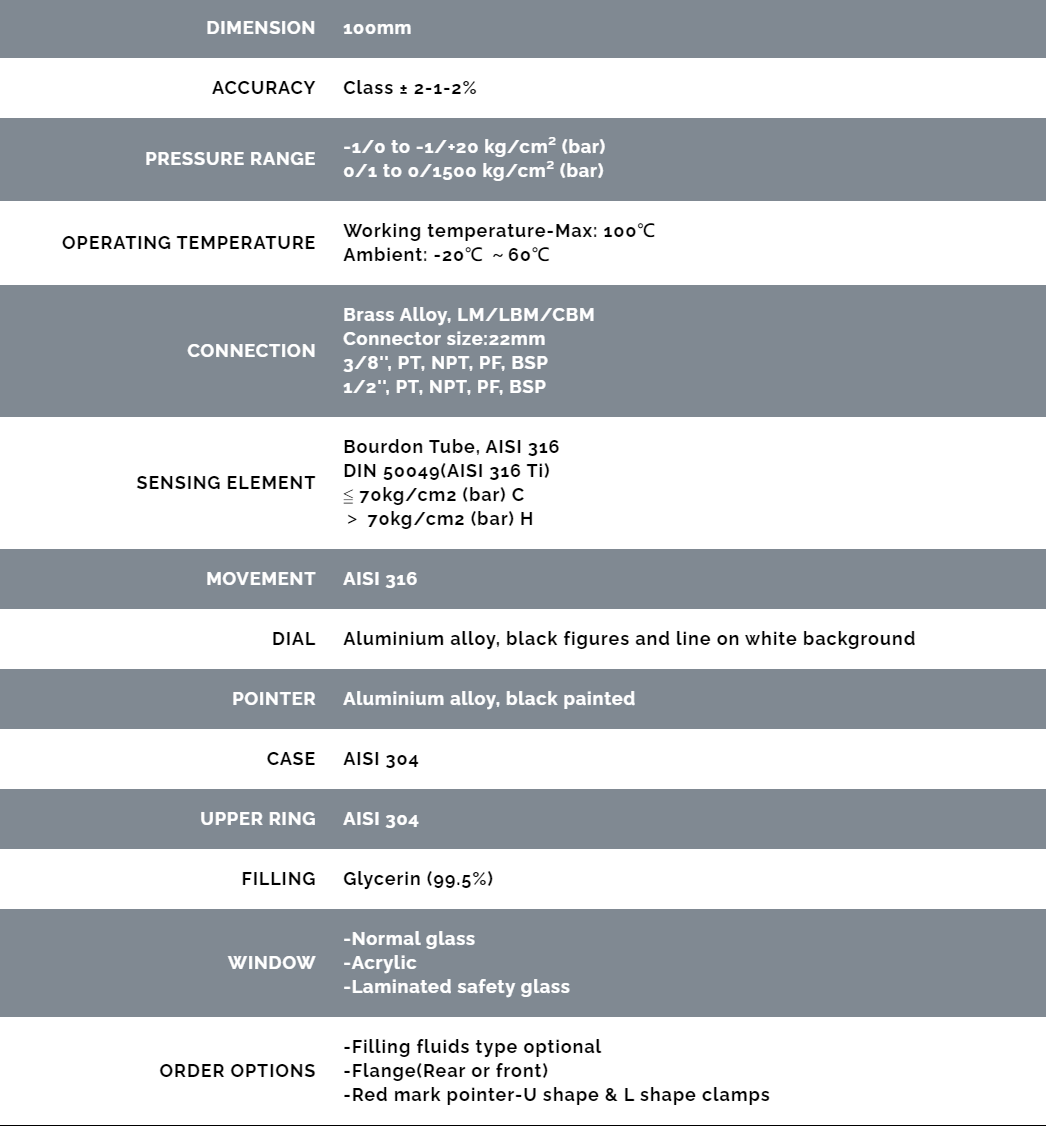

Specifications:

General structure of pressure gauge:

Pressure gauges are usually composed of the following parts:

- Meter body: The outer casing of the pressure gauge is usually made of stainless steel, which is highly resistant to corrosion in the air.

- Watch face: made from tempered glass/regular glass/plastic

- Display face: Is the part used to display the measurement parameters of the watch.

- Pressure container: often used for fluid entry, the material of the container will often be the same as the material of the meter leg.

- Measuring needle: Connected to the internal transmission unit, to display measured data information to the user.

- Movement: Is one of the parts that plays the main role in measuring and giving data to the measuring needle to operate.

- Clock feet: Designed with many other types of connections such as: threaded connection, flange connection, clamp connection. In addition, they can also be installed directly into pipes or indirectly through siphon pipes.

Operating principle of pressure gauge:

Mechanical pressure gauge:

The electronic pressure gauge operates when pressure is applied to the membrane that expands and contracts. At this time, the slider will move to the current parameter, and at the same time cause the magnetic field to change, affecting up the clock. This helps users easily observe and know the pressure to be measured on the watch face.

Electronic pressure gauge:

When fluid passes through the pressure gauge, the pressure will cause the copper tube (bourdon) to expand and at the same time pull the transmission part to work, and cause the watch hand to rotate when connected to the gear. The clock needle operates to indicate pressure based on the pressure of the fluid passing through.