- Home/

- Category/

- Servo Motor/

- Step motor Moons'

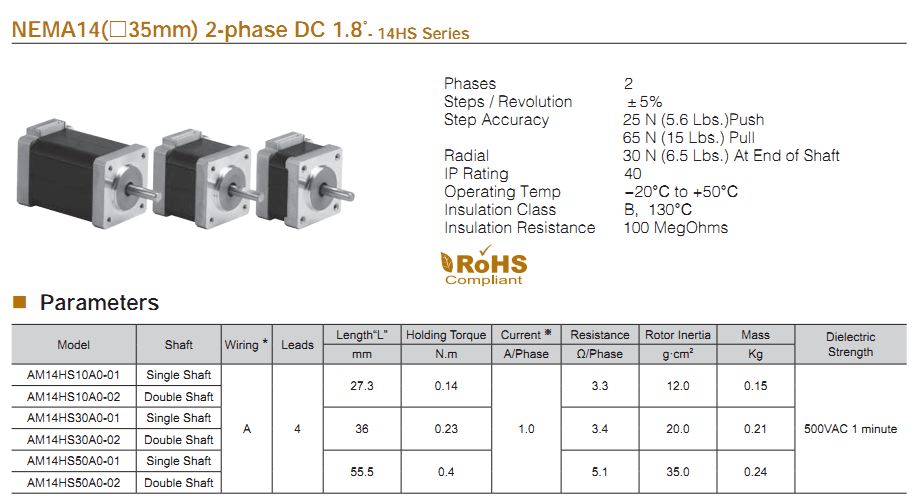

/ NEMA 14 (35X35MM) 2PHASE DC 1.8° Moons' step motor

NEMA 14 (35X35MM) 2PHASE DC 1.8° Moons' step motor

High torque Long life, low loss Small size, high efficiency Options : Connection wire, Coupling, Damper

- AM14HS10A0-01

- AM14HS10A0-02

- AM14HS30A0-01

- AM14HS30A0-02

- AM14HS50A0-01

- AM14HS50A0-02

- moons

- MS14HS1P4100

Description

Specification:

High Torque

High torque is mainly attributed to many factors including rare earth magnets, optimized rotors, Stators with maximum winding fill and laminatins, all of which are combined together to realize maximum torque.

MOONS’ high torque stepper motors provide 15% to 25% more torque across the entire speed than conventional motors.The increased torque is a result of higher motor efficiency, and is available without increasing the drive voltage or current.

Long Life Time

Step motor life is usually determined by the life of the bearings. MOONS' large ball bearing is optimized for short repatitive moves to ensure long life - generally 5 times longer than conventional motors, which means future huge cost saving of the replacement or repair of conventional motors.

In typical industrial application, the MTBF (Mean Time Between Failures) of MOONS' motor was up to 406,500 hours and lp (Failure Rate) was 3.44 hours per 1000,000 hours, In typical commercial application, the MTBF (Mean Time Between Failures) of MOONS' motor was up to 1,123,600 hours and lp (Failure Rate) was 1.21 hours per 1000,000 hours, which significantly ahead of competitor's motors.

Lower Heat

The design of MOONS' motor selected with new materials gets a lower resistance value when compared with motors of the same thickness and the same torque, this makes a greater degree of improvement for the thermal conductivity performance of the motor, thus greatly reduces the temperature rise of the motor.

Low Noise & Smooth

Improved manufacturing processes enable all components of MOONS' stepper motors to achieve better matching precision and more stable internal structures. This reduces vibration and noise effectively when the motor operates, which makes MOONS' stepper motors stand out by providing quieter and smoother operation.

Ongoing Tech Support

Get free and expert technical supports service directly from online application engineers with the backup of R&D engineers who designed and manufactured your product by online chat, inquiry Email.

Safely Packaging

In order to ensure your shipments withstand the long trip and arrive safely and intact, MOONS' specially designed Individual package to pass the drop test with its stable structure. Besides, the package is made from recyclable materials, providing you with professional safety delivery.

Link detail product: https://www.moonsindustries.com/series/nema-14-standard-hybrid-stepper-motors-b020103