- Home/

- Category/

- Slider, linear guide, lead screw PMI/

- MSB Series Compact Type

/ MSB-TS/S/LS Series Compact Type

MSB-TS/S/LS Series Compact Type

The trains of balls are designed to a contact angle of 45° which enables it to bear an equal load in radial, reversed radial and lateral directions. Therefore, it can be applied in any installation direction. Furthermore, MSA series can achieve a well balanced preload for increasing rigidity in four directions while keeping a low frictional resistance. This is especially suit to high precision and high rigidity required motion. The patent design of lubrication route makes the lubricant evenly distribute in each circulation loop. Therefore, the optimum lubrication can be achieved in any installation direction, and this promotes the performance in running accuracy, service life, and reliability.

- MSB 15

- MSB 15TS

- MSB 20S

- MSB 20TS

- MSB 25S

- MSB 25TS

- MSB 30S

- MSB 30TS

- MSB 35LS

- MSB 35S

- MSB 35TS

Description

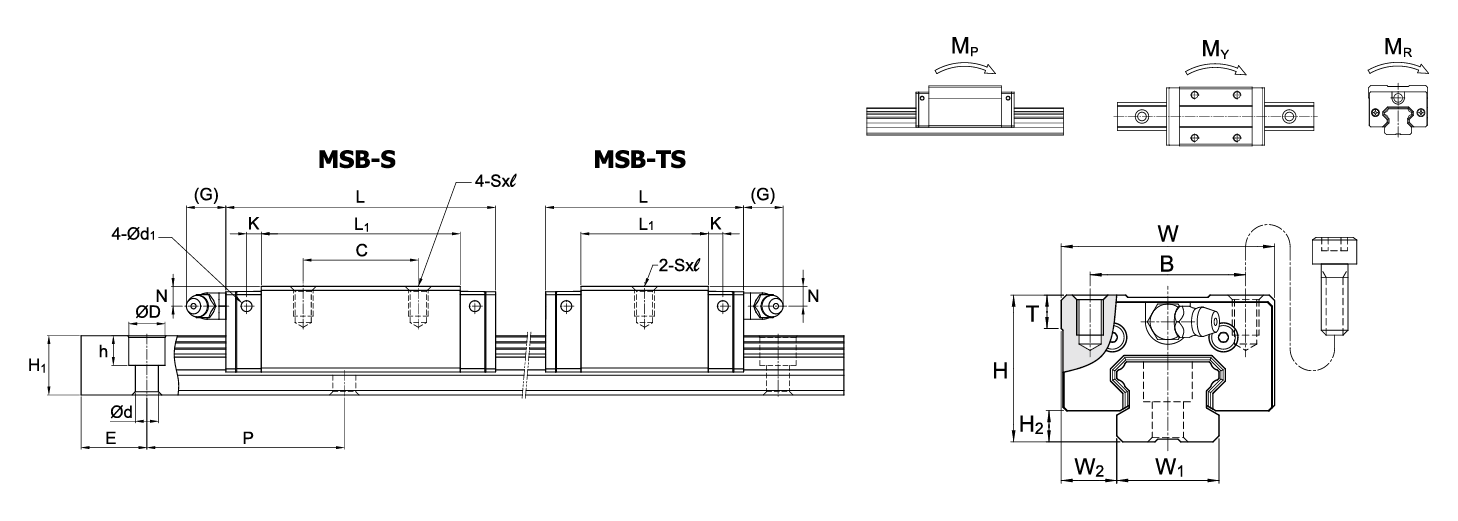

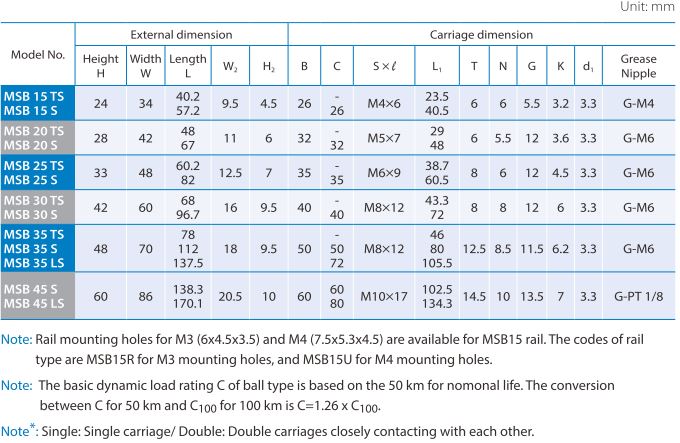

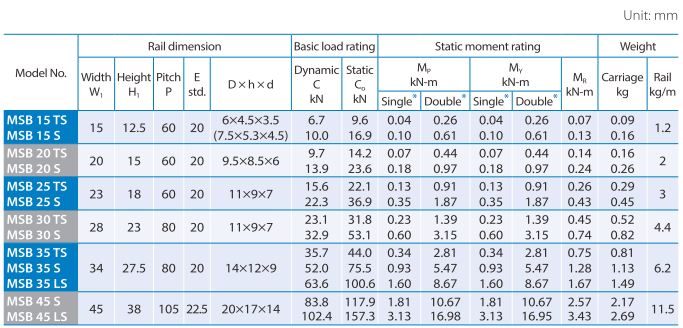

Specification:

Feature:

High positioning accuracy, high repeatability

The PMI linear guideway is a design of rolling motion with a low friction coeffi cient, and the diff erence between dynamic and static friction is very small. Therefore, the stick-slip will not occur when submicron feeding is making.

Low frictional resistance, high precision maintained for long period

The frictional resistance of a linear guideway is only 1/20th to 1/40th of that in a slide guide. With a linear guideway, a well lubrication can be easily achieved by supplying grease through the grease nipple on carriage or utilizing a centralized oil pumping system, thus the frictional resistance is decreased and the accuracy could be maintained for long period.

High rigidity with four-way load design

The optimum design of geometric mechanics makes the linear guideway to bear the load in all four directions, radial, reversed radial, and two lateral directions. Furthermore, the rigidity of linear guideway could be easily achieved by preloading carriage and by adding the number of carriages.

Suitable for high speed operation

Due to the characteristic of low frictional resistance, the required driving force is much lower than in other systems, thus the power consumption is small. Moreover, the temperature rising effect is small even under high speed operation.

Easy installation with interchangeability

Compared with the high-skill required scrapping process of conventional slide guide, the linear guideway can offer high precision even if the mounting surface is machined by milling or grinding. Moreover the interchangeability of linear guideway gives a convenience for installation and future maintenance.