- Home/

- Category/

- Slider, linear guide CPC/

- Slider, Linear guide CPC WRC Series

/ Linear Guide CPC WRC*MN / WRC*FN

Linear Guide CPC WRC*MN / WRC*FN

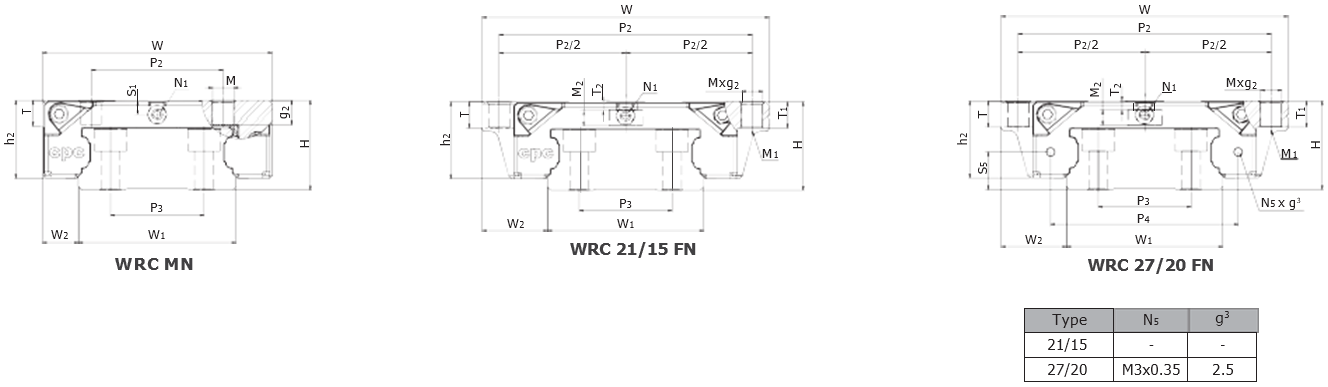

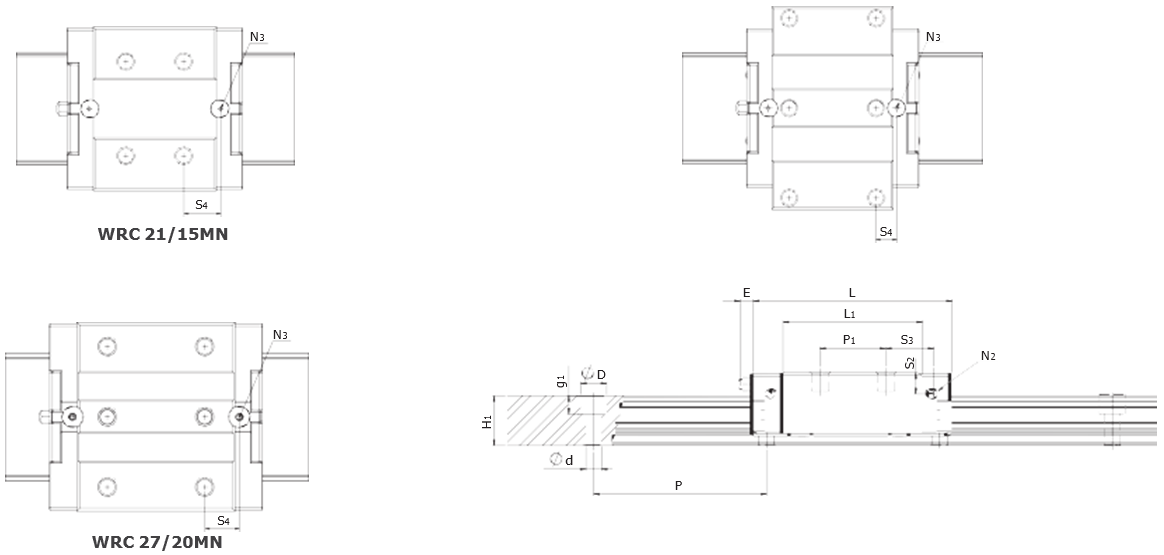

Linear Guide CPC WRC*MN / WRC*FN uses the O-type arrangement for its four-row ball circulation design. The 45-degree contact angle between the rails and balls allows our product to realize a four-directional equivalent load effect. cpc has placed special emphasis on strengthening the arm length (Lo) of our product so that when sustaining external force (F), this can have an even higher Mr value, which increases its rigidity and torsion-resistant capabilities. The larger and more numberous balls in our products allows it to have a 10-30% greater load capacity than similarily sized competitor products. These and other characteristics are the source of our product's high load capacity, moment, and stiffness features.

- Linear Guide CPC WRC

- WRC21/15MN

- WRC27/20MN

- WRC21/15FN

- WRC27/20FN

Design file download links:

STEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP filePDF fileDescription

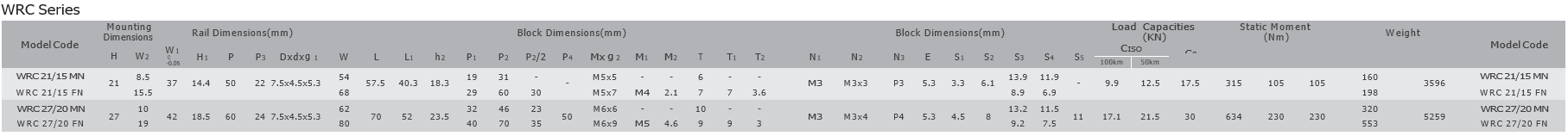

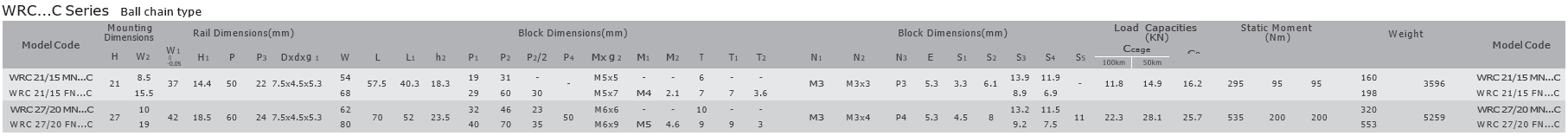

Specifications Linear Guide WRC*MN / WRC*FN:

Product Design Linear Guide CPC WRC*MN / WRC*FN:

- Dustproof design: The newly designed inner seals both protect the rails from foreign particles and keep the lubrication inside the runner block while maintaining a low friction profile.

- Bottom Seals: The bottom seals work in conjunction with the inner seals to keep foreign particles out and lubrication from leaking out. Our comprehensive sealing design significantly reduces re-lubrication needs and prolongs the service life of the runner block.

- End Seals: The end seals work in conjunction with the bottom and inner seals to block foreign particles out and prevent lubrication leakage. Our engineering plastic has a strong friction resistance and is less prone to cracking than typical NBR plastics.

- Standard Seals (S): Our standard seals are in direct contact with the rail surface, giving them increased dustproof and lubrication retention capabilities. cpc recommends this class of seal for blocks that operate in environments high in foreign particles, such as sawdust, for long periods of time. S-type seals will have comparatively higher friction than B-Type seals.

- Low Friction Seals (B): Our low-friction seals have slight contact with the rail and are suitable for most environments, with both low friction and a scraper function.

- Seal type friction comparison: Friction levels will be the highest on new linear rails. But, after short periods of operation, such friction will be reduced to a constant level.

Technical information Linear Guide CPC WRC*MN / WRC*FN:

If the block alone is subjected to torque from Mp and My directions, the maximum torque allowed for the block to run smoothly is 0.2 to 0.3 times the static torque. And the block with a larger preload will have a larger maximum allowable torque and vice versa. When the static moment Mp and My are greater than the maximum allowable torque, the block will jump when the ball rolls over the loaded/unloaded area in the block. If you have design problems mentioned above, please contact our technical department.

Installation instructions:

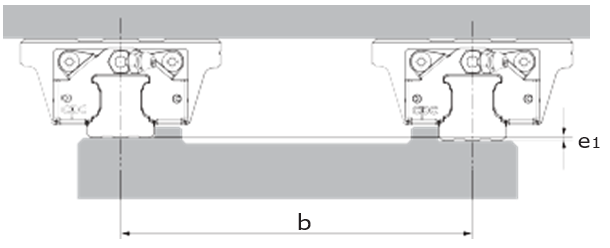

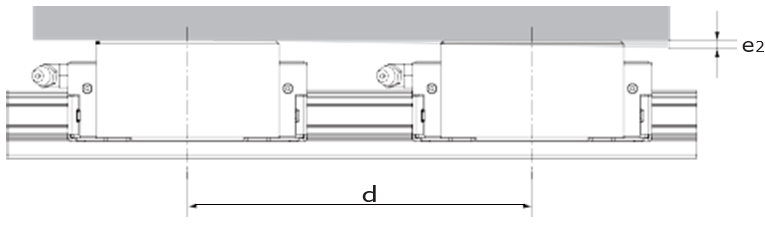

Installation surface geometry position accuracy Linear Guide CPC WRC*MN / WRC*FN

The rough finishing or milling on installation site will impact the working accuracy of linear guide, and reduce the service life of both standard, wide ball type linear guide and roller type linear guide. The accuracy of installation site and linear guides are critical factors to determine the accuracy of work bench. When the error of installation site is larger than the value calculated by following formula, the working resistance and service life will be impacted.

Detailed link of CPC HRC series products: https://www.chieftek.com/product-arhr.asp