- Home/

- Category/

- Slider, linear guide CPC/

- Slider, Linear guide CPC MR Series

/ Linear Guide CPC MR*ML / MR*MN

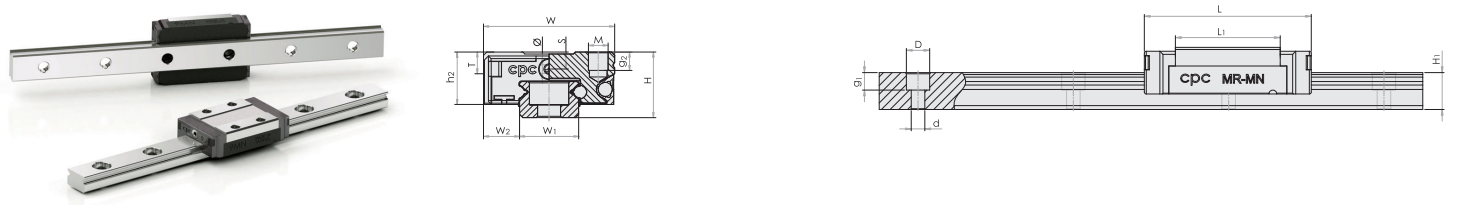

Linear Guide CPC MR*ML / MR*MN

Linear Guide CPC MR*ML / MR*MN In addition to a normally equipped end seal, a newly designed runner block is equipped with a extra bottom seal, which can prevent foreign objects entering via the lower side of the runner block into the ball running rail, extending the working life of the runner block.* the new design is recommended for purchase in priority.

- Linear Guide CPC MR

- MR5MN

- MR7MN

- MR9MN

- MR12MN

- MR15MN

- MR12MNZUV0N

- MR3ML

- MR5ML

- MR7ML

- MR9ML

- MR12ML

- MR15ML

Design file download links:

PDF fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileSTEP fileDescription

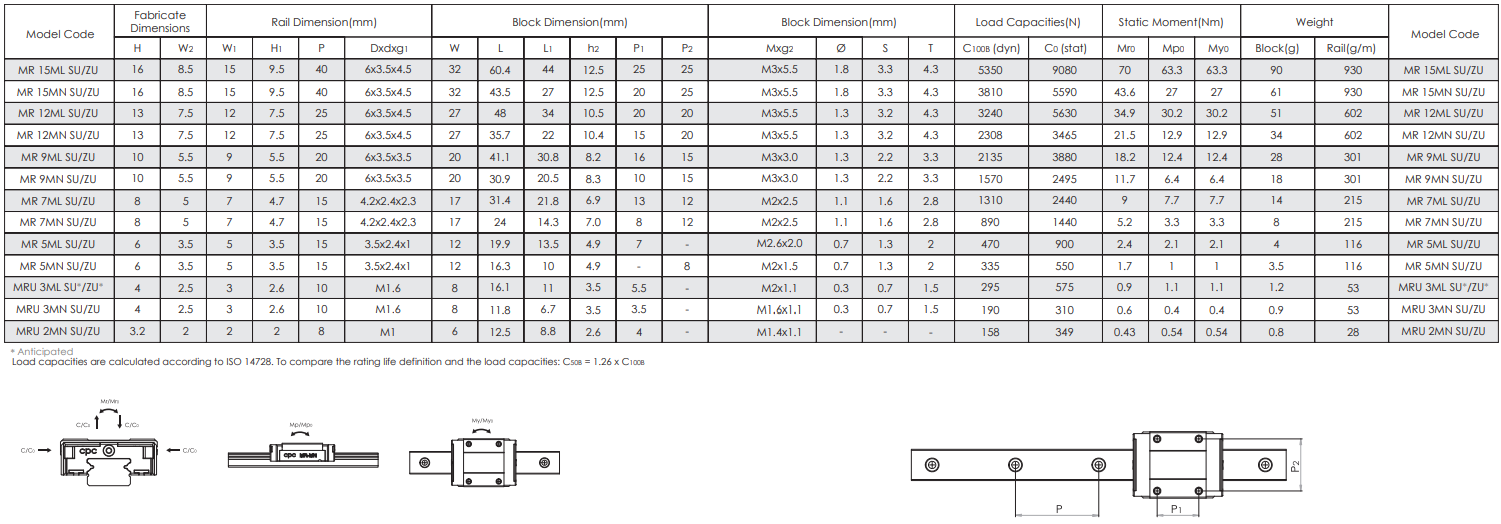

Specifications:

Embedded inverse hook design for reinforced mechanical integration

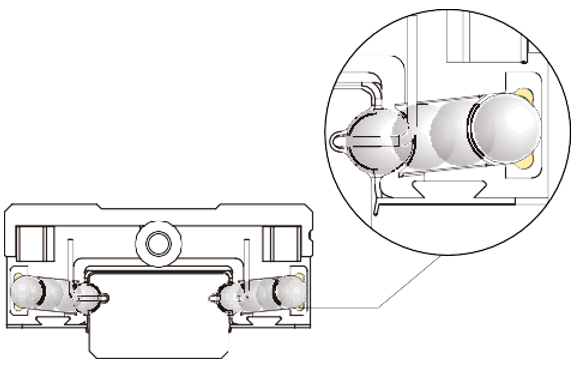

When the runner block is in motion and changing direction, the circulating stainless steel balls inside the raceway generate impact force against the plastic end cap. As the demand for rapid motion in the automation industry has increased, cpc has invented inverse plastic hooks to tightly secure our miniature blocks by effectively distributing the applied stress over a larger area.

High load and high moment capacity

The MR Miniature Linear Guide Series is designed using two rows of recirculating balls. The design uses a Gothic profile with a 45º contact angle to achieve an equal load capacity in all directions. Within the restriction of limited space, larger stainless steel balls are used to enhance load and torsion resistance capacity.

Under equal widthed rails, the black line indicated cpc linear guides provide greater surface contact as compared to competing products (indicated with the red-dotted line).

Dust Proof Design

Our standard design comes equipped with an end seal that effectively restricts dust contamination and prolongs lubrication, ensuring longer product life. Our specially- designed low friction seal slips do not affect running smoothness.

Lubrication - continued

- Re-lubrication shall be applied before the lubricant in the block is contaminated or changes color.

- The amount of the lubricant applied should be 1/2 of the first lubrication. When applying lubricant, this should be done until it seeps out from the device.

- Re-lubrication shall be applied under steady operating temperature, with the runner block moved back and forth throughout for optimum distribution.

- If the stroke is smaller than twice or greater than 15 times the steel body length of the block, the re-lubrication interval shall be shortened.

Re-lubrication Interval

The re-lubrication interval depends on individual use, as the speed, load, stroke length and operating environment are all factors. Careful observation of rails and blocks is the basis to determine the optimal re-lubrication interval; as a rule of thumb, re-lubricate at least once per year. Do not apply water-based coolant liquid on the linear rails or slide. Inject lubricant through injection holes on both ends of the runner block with the recommended cpc brand injector.

Detailed link of CPC MR series products: https://www.chieftek.com/product-mr.asp