- Home/

- Category/

- Pneumatic equipment Mindman/

- Air Treatment Unit

/ Air units MACP401

Air units MACP401

Compressed air filter is a connection device between compressed air equipment and water separator, responsible for ensuring the quality of compressed air source supplied for the entire production process. In addition, the filter also has the ability to maintain and adjust the pressure of the air compressor system to ensure the connection between machine parts and the air compressor. Because it has such an important role and task, air compressor users are very interested in this part.

- Air units MACP401

Description

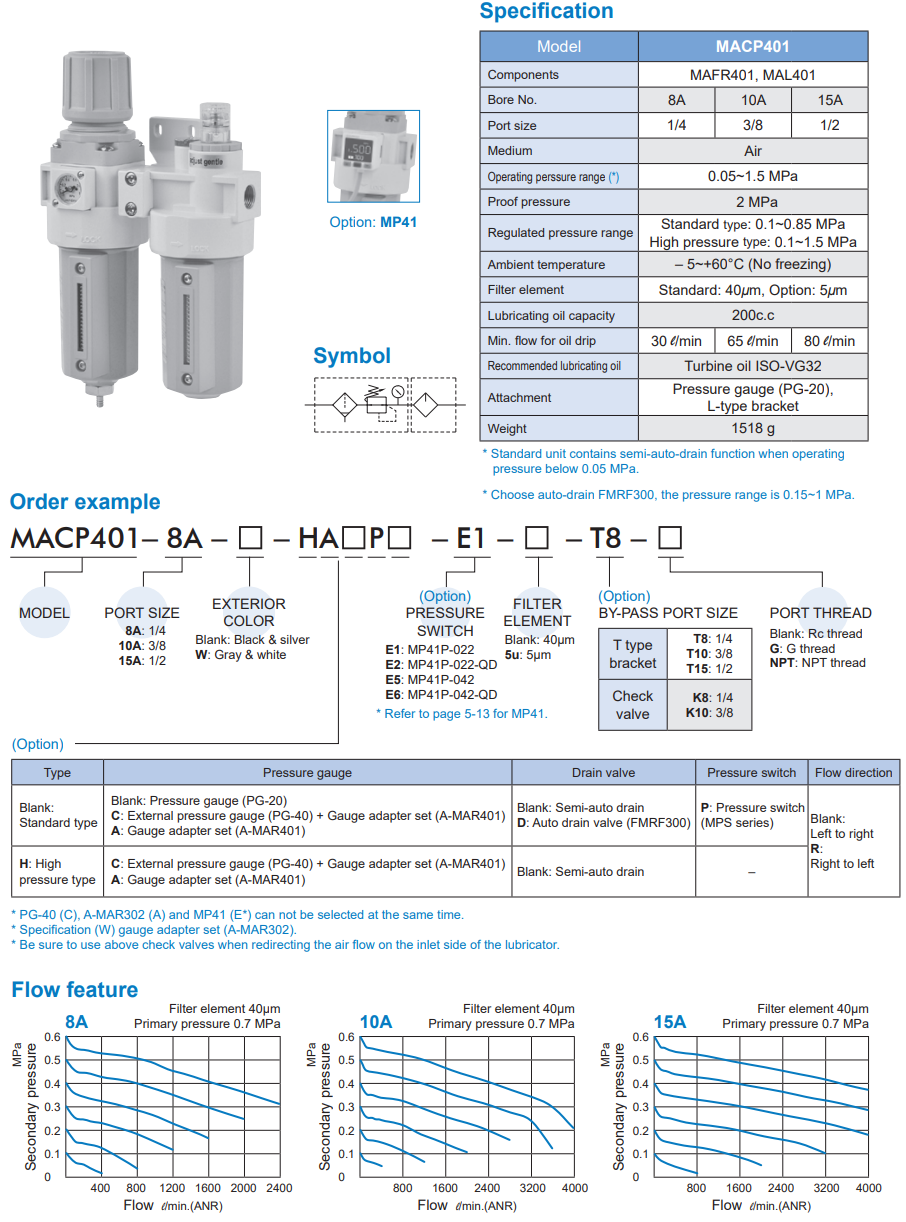

Specifications:

What is a compressed air filter?

Due to the influence of the tropical monsoon climate and environmental pollution, our country's air often has high humidity, containing many impurities such as dirt, metal particles, nylon scraps...

When these impurities enter the air compressor system, they will affect the quality of compressed air, causing reduced productivity and capacity of air-using equipment.

Therefore, compressed air filters are researched and produced to overcome this situation.

Compressed air filter is a device used to connect the compressed air supply with other devices in the system, with the function of separating water and removing impurities in the air.

In addition, the device also helps to adjust and maintain the necessary pressure in transmission devices, keeping machines operating stably, ensuring working performance and product quality.

Structure of compressed air filter

Filter valve

This is the component that determines the quality of compressed air after passing through the filter. The main task of the filter valve is to separate steam and remove impurities in the air source such as dirt, tiny metal particles, fabric dust...

Compressed air supplied from the power unit will be directed into the filter through the air duct. Here, due to the influence of high pressure, the gas will move in a vortex as it passes through the spiral metal shields to reach the filter elements.

Depending on the quality and properties of the injected compressed air, the size of the filter elements will be different. Typically, their magnitude will range from 5 µm to 70 µm.

The material used as the filter element is usually a synthetic material, woven metal or metal fiber.

In addition, with some high-quality systems, filter elements can be made from glass fiber with the ability to separate water and dirt up to 99.99%.

After the dirt moves in a vortex direction and splashes onto the filter screen, passes through the filter element and falls to the bottom of the cup, the automatic filter valve will automatically flush them out. If using a manual filter valve, the user needs to press the button to flush every time the dirt is full.

Pressure regulating valve

As its name suggests, a pressure regulating valve is responsible for adjusting and keeping pressure at a stable level, keeping the equipment safe even when the valve's input or output pressure fluctuates. They are often attached to pressure gauges so users can easily observe and control pressure levels.

When the output pressure increases compared to the regulated pressure, the amount of compressed air will increase affecting the valve diaphragm.

This causes the position of the shaft needle to change, and compressed air will escape to the outside environment through the air discharge hole.

That process repeats continuously until the air pressure returns to the original adjusted pressure level, and the shaft needle returns to the starting position.

Oil check valve

The oil valve is also known as the oil tank. This component can operate alone or in combination with the pressure regulator and water filter to create a compressed air filter. Their function is to contain lubricating oil and spray oil mist into purified compressed air. Oil will follow the gas to the joints, cylinders... to lubricate, reduce friction and cool.

Operating principle of compressed air filter

After the air is compressed, it will be directed inside the filter. Here, the air flow will move in a vortex form because of the impact from the spiral shields. This movement creates centrifugal force, causing water and impurities mixed in the gas to move through the air filter elements. These particles will remove about 95% of coarse dirt. About 5% of microscopic dust will continue to follow the air stream through a filter membrane to filter again.

All the dirt that passes through 2 filtrations will fall to the bottom of the filter cup and accumulate. When the cup is full, the filter automatically flushes, taking all the dirt out of the filter. As for the hand-rinsing filter, the operator needs to monitor the hand-rinsing process and remove dirt with the knob.

After being filtered, the compressed air will pass through the port to the pressure regulator (pressure regulating valve). Here, users can observe the compressed air pressure level through the display screen installed outside the filter. In case the compressed air pressure is too high, the user needs to adjust the pressure by turning the screw. If not adjusted promptly when the pressure increases, the air membrane will be pushed up to allow compressed air to escape to reduce pressure.

After passing through the pressure regulator, the compressed air continues to move to the oil valve. The amount of lubricating oil here will be sprayed in the form of fine mist so that the compressed air carries the oil through the pipeline into the working system.