What is a pneumatic cylinder?

Nov 11 2023Pneumatic cylinder, also known as pneumatic cylinder, air cylinder is a mechanical device that uses the power of compressed air to create force to provide movement. Pneumatic cylinders help convert the energy of compressed air into kinetic energy, which causes the piston of the cylinder to move, thereby transmitting power to the operating device. Because compressed air is expandable, there is no external energy input. To perform its function, compressed air expands at a pressure greater than atmospheric pressure, the pressure created pushes the piston to move in the desired direction.

What is a pneumatic cylinder?

Pneumatic cylinder, also known as pneumatic cylinder, air cylinder is a mechanical device that uses the power of compressed air to create force to provide movement. Pneumatic cylinders help convert the energy of compressed air into kinetic energy, which causes the piston of the cylinder to move, thereby transmitting power to the operating device. Because compressed air is expandable, there is no external energy input. To perform its function, compressed air expands at a pressure greater than atmospheric pressure, the pressure created pushes the piston to move in the desired direction.

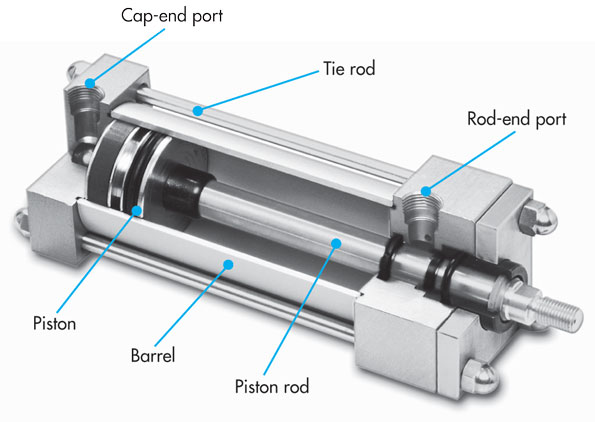

Structure of pneumatic cylinder

Pneumatic cylinders are composed of the following main parts:

- + Barrel

- + Pistons

- + Piston shaft (piston rod)

- + Cap-end port

- + Rod-end port

The farthest stroke that the piston shaft can move (called cylinder stroke) is a unit that is custom designed to suit appropriate requirements, depending on the manufacturer or the factory's running volume.

Classification of pneumatic cylinders

On the market there are many types of pneumatic cylinders with different designs, types, and origins. The following types of pneumatic cylinders are the most common types of cylinders.

One-way pneumatic cylinder

One-way pneumatic cylinders are also known as single-acting pneumatic cylinders. This type of pneumatic cylinder uses compressed air to move the piston in a certain direction of motion. The piston returns to its original position thanks to the force of a spring or an external push. When looking at one-way pneumatic cylinders, you can see that they have a compressed air supply hole and a compressed air exhaust hole on the body. Normally, when using a 1-way pneumatic cylinder, people use a 3/2 pneumatic solenoid valve (3-way 2-position solenoid valve) to adjust the compressed air flow.

One-way pneumatic cylinders have two basic forms:

- + Piston-type pneumatic cylinder

- + Diaphragm-type pneumatic cylinder.

2-way pneumatic cylinder

2-way pneumatic cylinders are also known as double-acting pneumatic cylinders. This is a type of pneumatic cylinder with actuators at both ends. 2-way pneumatic cylinders use the force of compressed air to push and retract. Piston thrust is generated from both sides, so the structure of a 2-way pneumatic cylinder has 2 holes to supply compressed air. With this type of 2-way pneumatic cylinder, people use 4/2, 5/2 or 5/3 type solenoid valves to adjust compressed air flow.

The outstanding feature of most 2-way pneumatic cylinders is that the piston rod is only on one side, so the sizes of the two piston heads are different, leading to completely different forces acting on the piston rod. On the market today there are 2 types of 2-way pneumatic cylinders:

- + 2-way pneumatic cylinder without damping pad

- + 2-way pneumatic cylinder with damping pad, adjustable stroke

A 2-way synchronous pneumatic cylinder is a cylinder with piston rods on both sides, equal areas on both sides, and the force generated on both sides is almost completely equal.

Some other popular types of pneumatic cylinders

- + Rotating pneumatic cylinder

- + Sliding pneumatic cylinder (pneumatic sliding cylinder)

- + Electro-pneumatic cylinder

- + Pneumatic stainless steel cylinder: Pneumatic stainless steel cylinder is a type of cylinder made of stainless steel, ensuring the device operates durably over time.

- + Round pneumatic cylinder

- + Square pneumatic cylinder

Uses of pneumatic cylinders

Have you ever wondered what the use of a pneumatic cylinder is? Let's take a look at some industries that use pneumatic cylinders.

- + Pneumatic cylinders used in smart doors

- + Pneumatic cylinders used in industrial production

- Pneumatic cylinders today are widely used in industries such as assembly, processing, wood industry, robot manufacturing,...

- + Pneumatic cylinders used in the construction field

Jade M-Tech Co., Ltd. we are like a link that creates a bridge between MINDMAN manufacturers and customers. Customers go to dealers to find satisfactory products, professional consulting team. and reasonable price.

As an agent in Vietnam, Jade M-Tech Co., Ltd. will always get the agency's benefits from MINDMAN, we will always update customers with the most effective policies and information.

* Currently on the market there are many different brands of pneumatic equipment, but MINDMAN is the dominant product made in Taiwan according to the most modern production technology, stable operation with durability and accuracy beyond dominant. So when there is a need for MINDMAN products, please contact our company for the best advice and quotation.