What is a riveting machine? Address providing reputable imported riveting machines.

Jan 28 2024The riveting machine is used to connect metal panels, plastic panels, and details without causing deformation to the product. The product's details are fastened with nails after riveting. The use of riveting machines facilitates production because the number of rivets produced is very large, so developing a machine to supply rivets and mass process rivets is very necessary.

Application of riveting machine in industry

Rivet riveting machines are often used to make latches for specific products such as making pliers, driving hinge latches, driving rivets for upholstery, making scissors, car seat hook latches, and positioning pins for many metal plates. ,

Automatic riveting machines can perform a combination of operations: leveling the part face, holding the workpiece, drilling and boring holes, placing rivets and riveting caps.

Classification of riveting machines

There are two types of riveting machines: stamping riveting machines and orbital riveting machines. Punching riveting machines are often used to lock materials together, used when you want to limit the movement of details. The rotary riveting machine is used to connect parts together but still want parts to be able to move such as scissors, pliers, etc.

How to classify riveting machines according to the criteria of aluminum riveting machines, pneumatic steel riveting machines and hydraulic riveting machines

- The machine uses an electric or pneumatic motor to control the compression force of the punch head on the rivet.

- The machine is often used to rivet hollow rivets or solid aluminum rivets.

- Pneumatic riveting machines use air with a pressure of 4-8bar (Mpa) to rivet.

- These types of stamping machines are often used to rivet rivets with small diameters from Ø1- Ø9mm. Often used to rivet simple rivets.

- With the advantages of small size and low voltage, it is widely used in the market.

- Orbital riveting machines, also known as riveting machines, are often used to rivet solid rivets rather than hollow rivets.

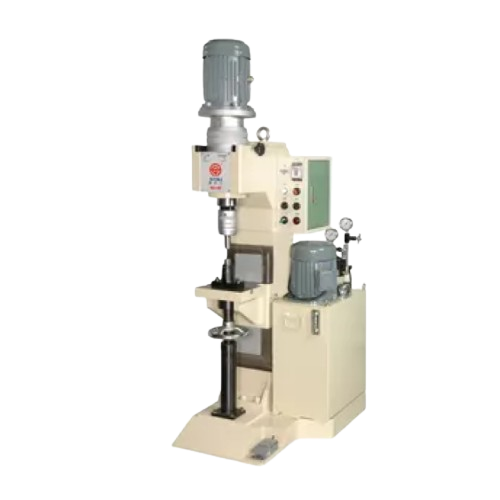

- Hydraulic riveting machines use oil pressure to create compression on the rivet head.

- The machine uses a powerful hydraulic motor so it can be used to rivet large diameter rivets, durable, can rivet solid rivets from Ø10- Ø25mm, hollow rivets up to Ø40mm.

- Hydraulic riveting machines can also be installed with a dividing head to be able to rivet 2-3 products at the same time in 1 riveting operation.

- The hydraulic riveting machine has an additional oil tank, so the machine capacity will be higher than the pneumatic riveting machine, and the machine size will be larger because it requires an additional hydraulic oil tank.

- Summary: Depending on the type of product and function of the product, customers can choose the type of riveting machine as required.

Be careful when using riveting machines

- Regularly lubricate the bearing in the swivel head to ensure perfect riveting.

- If the machine is operated in cold or hot weather, please replace with specified hydraulic oil.

- The machine must be regularly cleaned and maintained to ensure best performance

- The punch head will wear out and the exact size will be wrong. Whenever its length is shorter than the standard length of 3 mm, it is necessary to replace the punch head with a new one.

- When the pressure is set too low, the bearing inside the chuck is easily damaged.

Outstanding features of pneumatic riveting machine

- The pneumatic riveting machine is a standard, pneumatically controlled riveting machine designed as a workbench type. This riveting machine model is specialized for riveting solid iron or steel rivets. This riveting machine model is specialized for riveting solid iron or steel rivets.

- Basic adjustment: The orbital head can be raised and lowered.

- Micro-adjustment: The screw cap is equipped with an index scale used for micro-adjustment.

- The counter on the control panel can be used to count the number of scattered pieces.

- Outstanding features of the pneumatic riveting machine

- This is the newest forming and riveting process, instead of spinning, punching, pressing, welding, turning, riveting results in a very smooth metal surface, it will greatly increase output and save electricity.

- Increase output greatly and save labor costs.

- The good quality of all parts on this machine ensures a smooth workpiece surface and the stability of the machining process.

- Double air regulators can be used to control the riveting speed effectively.

- The air duct is equipped with an air filter to prevent moisture.

- Acceptable for hollow rivets, semi-tubular rivets, solid rivets.

- Easy operation and operation.

- Vertical style, desk design, helps workers relax and feel comfortable.

- Driven by compressed air.

- Take small area, easy to maintain, very easy to replace worn parts by workers.

- High yield and economic price.

- Safety devices to prevent injury to people.

As a level I agent in Vietnam, Jade M Tech Co., Ltd. will always have the benefits of an agent from Atoli, we will always update customers with the most effective policies and information.

- Always get price support

- Always provided with advertising materials, product introductions, technical documents, and catalogs

- Receive product technical consulting support from Atoli experts

- Regularly updated information about new technology and new products.

- In addition, Atoli also has enough documents for users to be completely assured about the quality of the product

+ Import and Export Documents (C/O),

+ International Quality Certificate (C/Q)

In addition, as a level I agent in Vietnam, Jade M tech Co., Ltd. currently owns a large warehouse with a complete, diverse and rich range of Atoli products. Ensuring that all customers are always available. quantity of orders requested by customers and quick delivery.

We guarantee that when you come to Jade M tech, you will find and own quality Atoli product lines to solve your needs.

With all the efforts and efforts of Jade M Tech Co., Ltd. to provide customers with products that are stable in quality and competitive in price.

For further information, please contact: Jade M Tech Co., Ltd

Email: [email protected] or Phone number/Zalo: 0935136236

Thank you very much!