What is a Stepper Motor?

Dec 02 2023Stepper Motor (step motor), also known as stepper motor, is a type of DC electric motor that moves in discrete steps, consisting of many coils organized in groups (called phases). By energizing each phase in sequence, the motor will rotate one step at a time. Stepper Motor is essentially a synchronous motor used to convert control signals in the form of consecutive discrete electrical pulses into rotational movements or rotor movements and has the ability to fix the rotor to different positions. necessary location. With a computer-controlled step, you can achieve very precise positioning. Because of this, stepper motors are a popular choice for many precision motion control applications.

Structure

Basically, stepper motor consists of two main components: Stator and Roto. In particular, the stator is made of magnetic iron on a body with many small grooves designed to easily place the coil. Rotors (also known as permanent magnets) are arranged carefully and thoroughly on top of each other. These magnet leaves are arranged symmetrically with each other and divided into pairs.

Operating principle and classification of Stepper Motor

Principle of operation

The stepper motor does not rotate according to a normal mechanism but rotates step by step so it has high controllability. Stepper motors work thanks to electronic switches. These electronic circuits will inject control command signals into the stator in a certain order and frequency. The total number of rotation angles of the rotor corresponds to the number of switching times, as well as the rotation direction and rotation speed of the rotor depends on the switching order and switching frequency. As follows:

Full-step control (wave drive – 1 phase on)

The advantage of this control method is that it is simple, but its capacity is very low, only reaching 25% for unipolar stepper motors, and reaching 50% for bipolar types. Therefore, the torque generated by this form of control is relatively weak.

Full-step control (two phase drive – 2 phase on)

In this form of control, the two coils will be supplied with energy at the same time, so the output is higher than the above form.

Half-step control (1 or 2 phase on)

Half-step control type is a combination of the above two types.

Classify

Classified by rotor

If classified by rotor, stepper motors are divided into 3 types:

- Type 1: Step Motor has a rotor that is actuated by a wound wire or permanent magnet.

- Type 2: Stepper motor has rotor but is not activated. However, they have parts from induction and resistance. This is also known as a variable reluctance stepper motor.

- Type 3: Stepper Motor has a rotor structure that combines both of the above types.

Sort by polarity

If classified by polarity, stepper motors are divided into 2 types:

- Type 1: Unipolar Stepper Motor, including permanent magnet or mixed type stepper motors. The coils always have a center end connected from the center of each coil.

- Type 2: Bipolar Stepper Motor, including permanent magnet or variable reluctance stepper motors. The characteristic of the bipolar Stepper Motor is that the coils do not have a wire connecting from the center.

Classified by phase number

If classified by number of phases, stepper motors are divided into 3 types:

- Type 1: 2-phase stepper motor, including 4 wires, 6 wires or 8 wires.

- Type 2: Stepper motor type 3 phase, includes 3 wires or 4 wires.

- Type 3: 5-phase stepper motor, with 5 wires or 10 wires.

Advantages and practical applications of Stepper Motor

Advantage:

In the right environment, a stepper motor can be ideal because there is adequate stopping torque and the motor's rotation angle is proportional to the input pulse. Essentially, stepper motors provide excellent speed control, precise positioning and repeatability of movements.

In addition, stepper motors are highly reliable because they do not have contact brushes inside the motor. This minimizes problems that may occur during operation and maximizes engine life. Stepper motors can be operated in many different environments, achieving many different rotation speeds because the speed is proportional to the frequency of the pulse input.

Practical application

Currently, stepper motors are mainly used in digital motion control and automation industry, especially for devices that require precision. For example, industrial machines serving mechanical processing: CNC plasma cutting machines, laser cutting machines... In addition, in computer technology, stepper motors are also used for hard drives, hard drives. floppy disk, printer…

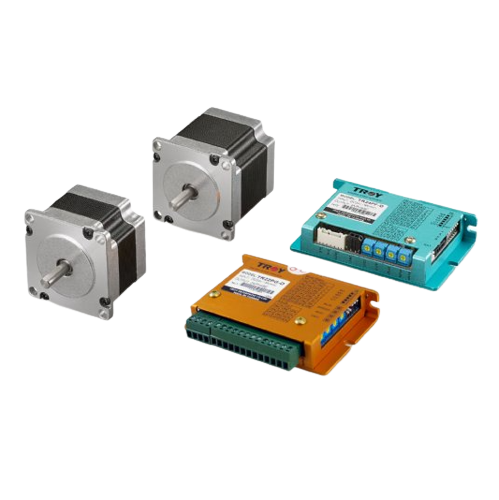

Jade M-Tech Co., Ltd. is like a link creating a bridge between Troy manufacturers and customers. Customers come to agents to find satisfactory products and a team of professional consultants. and reasonable price.

As an agent in Vietnam, Jade M-Tech Co., Ltd. will always have the benefits of an agent from Troy, we will always update customers with the most effective policies and information.

* Currently on the market there are many different brands of pneumatic equipment, but Troy is the dominant product manufactured in Taiwan using the most modern production technology, operating stably with outstanding durability and accuracy. dominant. Therefore, when you have a need for Troy products, please contact our company for advice and the best quote.