Structure of Bench Drilling Machine and How to Use It Safely

Oct 10 2023In today's industries, bench drills are quite commonly used. Bench drilling machines are a line of equipment that provide the ability to drill holes accurately at a very fast speed on many materials such as steel and wood. However, use will require workers to have a certain understanding of the structure of bench drills.

What is a bench drill?

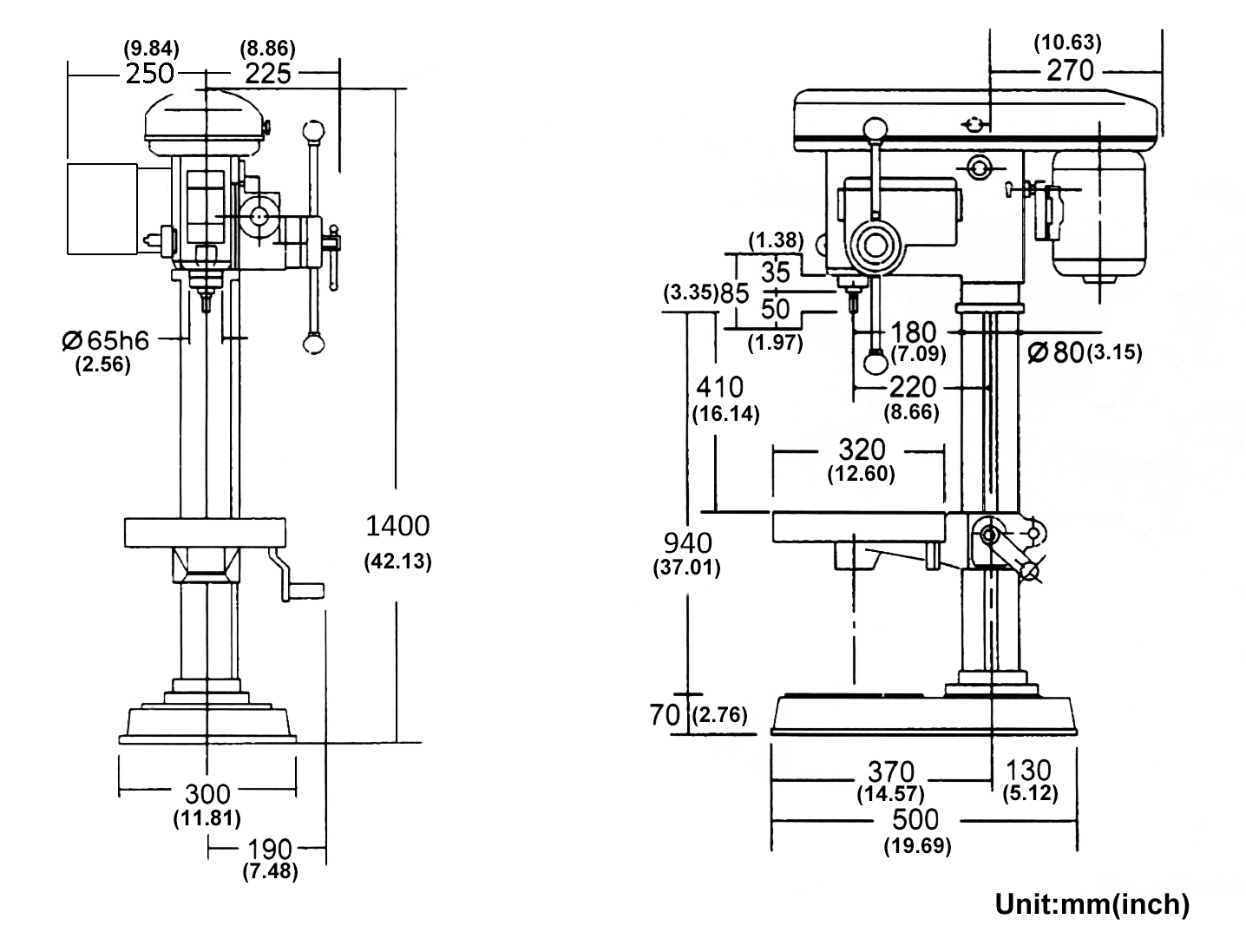

Bench drilling machine is a line of equipment commonly used in industry that has a vertical cylindrical shape, equipped with an electric motor mounted on the top of the cylinder head. The cylindrical body is constructed from steel, iron or sintered alloy with polished plating. At the same time, the machine has a square or rectangular iron base, keeping the device upright on the surface.

Structure of bench drilling machine

Bench drills can use 3-phase or 1-phase power. Specialized for drilling wood or drilling metals such as steel and iron in many industrial and mechanical industries.

Consists of the following main parts:

- Dashboard

- Take the journey

- Main shaft crank

- Desk

- Engine

- Hand cranks drill head

- Knife box

- Machine body

The bench drill has an extremely sturdy design with a tripod structure made from high-quality durable metal. The drill motor is capable of meeting strong and durable working requirements. The machine's working table can be flexibly adjusted to suit your needs. In general, the device has a quite different design compared to the structure of a hand drill.

Principle of operation

The bench drilling machine operates according to the following principle:

The tool spindle, also known as the drill, can be advanced automatically either by the workpiece or by the user's hand. The worktable is designed to hold workpieces rigidly in one position. At this time, the rotating edges of the drill exert a great force on the workpiece and the drill hole is formed. The removal of metal during the hole making process is due to the cutting and extrusion capabilities in the bench drill construction.

Uses of bench drills

The main use of the bench drill line is to drill holes accurately in materials such as aluminum, iron, steel and other mixed materials. In addition, some advanced machine models also have the ability to cut and tap.

How to use a bench drill

The bench drill operates with high capacity, providing fast processing speed in drilling on solid material surfaces with relatively simple usage steps as follows:

- Step 1: Fix the drill bit to the clamp head

- Step 2: Choose the appropriate voltage to use.

- Step 3: Adjust the machine's working speed.

The working speed of a bench drill depends on the diameter of the drill bit:

- Diameter less than 5mm: Fast speed.

- Diameter from 5mm - 8mm: Moderate speed.

- Diameter from 8mm - 11mm: Slow speed.

- Diameters larger than 11mm need to use a hole punch to drill first and then use a drill bit at a higher speed.

Notes on maintenance and use of bench drills

Be careful when using a bench drill

- Read the user manual carefully before operating the bench drill.

- Turn the switch to the off position before plugging in the operating power source to avoid suddenly starting the drill.

- The tool used for adjustment should be removed from the machine before starting.

- Use goggles to keep debris from getting into your eyes.

- Supervise carefully during operation because the machine operates very strongly and can cause dangers that the user cannot foresee.

- Must use the drill with the correct design capacity on the label, do not force the load, which will reduce the life and performance of the machine.

Maintenance of bench drilling machines

- Make sure the machine and ventilation slots are clean.

- Do not force the drill to overload.

- Turn off the power when replacing components.

- Change lubricating oil periodically.

- Remove sharp accessories and store the device in a dry place, out of reach of children.

Jade M-Tech Co., Ltd. is like a link that creates a bridge between AIRBEST manufacturers and customers. Customers go to dealers to find satisfactory products, professional consulting team. and reasonable price.

As an agent in Vietnam, Jade M tech Co., Ltd. will always get the agent's benefits from Yi-chang , we will always update customers with the most effective policies and information.

* Currently on the market there are many different brands of Bench drills machine, but Yi-chang is the dominant product made in Taiwan according to European manufacturing technology, stable operation with outstanding rigidity and precision. Therefore, when there is a need for Yi-chang products, please contact our company for the best advice and quotation.